Changing the wood stove’s antiquated format.

The Wood Stove Decathlon was created to focus more interest in designing the next generation wood stove. Clean burning, efficient stoves are becoming ever more important as the use of wood for residential heating has increased by 40 percent since 2004 and because wood is the primary source of heat for roughly 2.3 million U.S. households. In Europe, wood heat has been popular for well over 500,000 years and is still ‘the’ primary source of renewable energy.

Today’s Wood Stoves Waste Too Much Energy

Currently the majority of wood stoves in use deliver only 40 to 50 percent of the energy potential of the wood, this is highly wasteful. But on a bright note, many of the prototype models entered into the decathlon squeezed out more than 90 percent of the wood’s energy potential and burned much cleaner than older stoves.

The 14 finalists were judged on the following:

- Innovation (10 points)

- Market appeal and user friendliness (10 points)

- Affordability (10 points)

- Emissions (10 points)

- Efficiency (10 points)

The 14 finalists that were invited to the 2013 competion were Dragon Heater, Firemaster, Helbro Stoves, HWAM, Intercontinental, Kimberly, Mulciber, Ofenbou and Feurerstellen, Smartsove, Travis, Tulikivi, Walker Stoves, Wittus, and Woodstock Soapstone.

Wood Stove Decathlon Results

Woodstock Soapstone won the $25,000 first prize. The $10,000 second prize was shared by Wittus-Fire by Design and Travis Industries.

Winners for individual categories were HWAM for innovation; Travis Industries for lowest carbon monoxide emissions and also for market appeal; IntensiFire for affordability; the University of Maryland’s Mulciber for lowest particulate emissions; and Woodstock Soapstone for efficiency.

The event was sponsored by the Alliance for Green Heat, the U.S. Forest Service, the New York State Energy Research and Development Authority, and industry groups seeking to improve the efficiency of wood-burning appliances.

First Place, Grand Prize

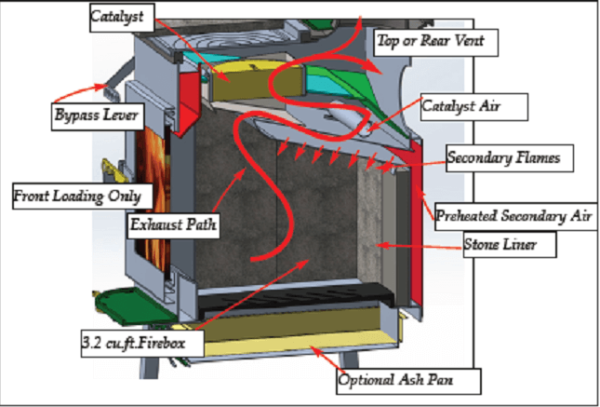

Woodstock Soapstone won with the Ideal Hybrid, an affordable, very high efficiency stove with very low emissions. The steel hybrid currently has the lowest “high burn” emissions on record. The stove uses an advanced hybrid combustion design incorporating both catalyst and secondary combustion. It has variable and self-regulating air/fuel ratio in order to maximize combustion efficiency and minimize emissions at all burn rates.

To prevent warpage of metal, to focus the heat on combustion and to store heat, the Woodstock Hybrid is lined with 1.125” thick soapstone on the side walls and contains firebrick on the inside bottom.

The catalytic combustor points at the top and front of the stove and therefore captures the heat in the stove body, rather than allowing that heat to be lost up the chimney.

The Steel Hybrid has a secondary combustion chamber that is angled making the outlets visible from the viewing window. The display of secondary combustion is always visible, and there is an almost infinite variety of secondary pyrotechnics in the top of the firebox depending on the burn rate, amount of fuel, and damper settings. Secondary combustion is mesmerizing and it also cues the operator/owner to understanding the amount of combustible material in wood smoke that would have otherwise gone up the chimney. Read more about catalytic reaction and secondary combustion here: woodstove.com

“We are essentially making a gasification stove,” says Tom Morrissey, the owner of Woodstock. “If you look at this thing when it’s burning, the fire does not look like what you would think of as a wood fire. The whole top of the firebox is like an inverted gas burner; there are 120 holes with a tube of flame coming out of each one.”

The Ideal Hybrid stove is not yet available, but you can reserve one.

The stove will come with custom-cut steel andirons, sides, and cooktops in a variety of paint finishes.

Woodstock stoves are made in New Hampshire.

Tied for Second Place and Lowest Emissions Prize: Travis Industries, Inc.

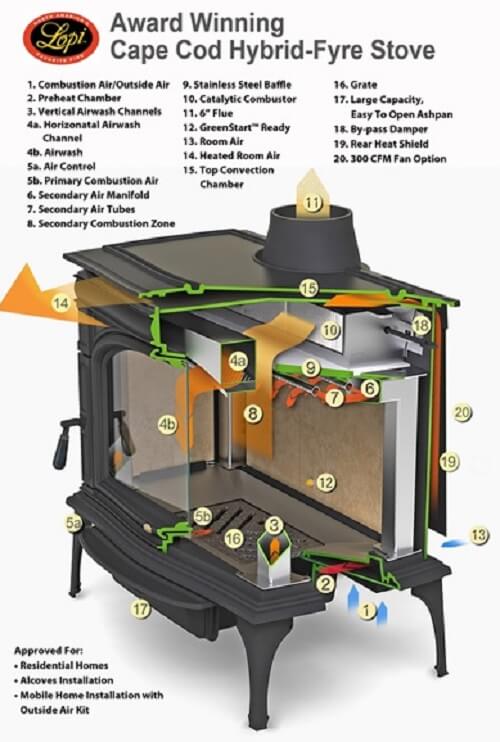

The Cape Cod™ is Lopi’s “Super Stove” boasting 80% efficiency with only 0.45 grams emissions per hour, making it the cleanest burning wood stove as tested on the U.S. market. This stove features a massive 3 cubic foot firebox and convection heat exchanger and was designed in durable cast iron.

The stove’s advanced secondary combustion system along with catalytic assist are what make this stove so clean and efficient. A convection chamber surrounds the firebox. Room air is drawn through the back convection chamber then circulated through the convection channel where it is heated. This hot air is then expelled from the top convection chamber. An optional fan pushes convection air through the stove, greatly improving heat transfer and air circulation into the room. The Cape Cod weighs in at almost 600 pounds. Heats up to 2500 sq feet. Approx. $4000.

Lopi stoves are made in Washington State, USA.

Lopi is a subsidiary of Travis Industries.

lopistoves.com

Tied for Second Place: Xeoos TwinFire

The Twinfire’s double-chambered combustion system is like no other.

Twinfire, a German import, heats wood to 1,400 to 1,800 degrees Fahrenheit (760 to 980 degrees Celsius) until it gives off flammable gases, which form a yellow blowtorch of flame that shoots downward below the grate that holds the wood. The gases burn cleanly and thoroughly. The patented Twinfire is 93 percent efficient, as tested by OMNI Labs, Portland, Oregon.

Gasification is the process by which carbon-based materials, which in this case is wood, are converted into combustible gases—principally carbon monoxide and hydrogen—by heating the fuel at high temperatures with a controlled amount of oxygen. The result of the gasification process is a highly efficient heat producer with a minimal amount of pollution.

In the Twinfire, the fire is started in the upper burning chamber. When enough flames and heat have built up to over 1800 degrees Fahrenheit, the handle is pressed down, and the heated gases pull down into the lower chamber and ignite into a blazing fire. These gases are reheated to create an almost total combustion with 93 percent efficiency and a low emission rate of 2.4 grams per hour.* The lower chamber is the exterminator that burns any remaining ash down to tiny bits.

The TwinFire’s hand-built body is made of 4 mm thick steel plate, its front frame is cast iron, the firebox is lined in vermiculite, the floor of the firebox is made of a special fire clay. The raised floor and fire grate are made of heat-resistant stainless steel. The Xeoos burns with normal chimney draft and the outlet can be placed on the top or rear.

The TwinFire retails for $5,900 for the base-level model, but could save hundreds of dollars a year on fuel. Heats up to a 1000 sq ft area. Imported into and showroom in Pound Ridge, NY.

Made in Germany.

U.S.: www.wittus.com

In Europe: xeoos.de

IntensiFire wins for Affordability

The IntensiFire is a downdraft metal insert that can be retrofitted to fit inside nearly any traditional wood stove. It can transform a dirty, old wood stove into a clean-burning, efficient stove.

IntensiFire was the only retrofit option in the design challenge. For the competition a 30 year old Treemont stove was retrofit. The IntensiFire placed 2nd for affordable low emission technology and third for innovation.

Jason Stewart of New Zealand is the inventor. Jason says “Why buy a new stove when for just a few hundred dollars you can install an IntensiFire insert and make your old stove perform like new? You’ll deliver up to 60 percent more heat into your home from the same amount of wood, so you save money using less while also lowering your carbon footprint. For the true conservationist, you also save the energy and resources required to make a new stove and dispose of your old one.” It will bring the benefits of secondary combustion air to older stoves that don’t have this function. Baffles are no longer required and the cost of the IntensiFire is around the same as the cost of a replacement baffle.

Jason shares on his website that during the testing there were several instances where the testing equipment was measuring zero emissions from the IntensiFire.

An added benefit of the IntensiFire is that it concentrates the energy of the fire and can cleanly burn 30 percent moisture content wood, or even higher if the pieces are cut smaller, provided that the stove is warmed up on dryer wood.

Currently made in New Zealand. $425.

www.facebook.com/Intensifire

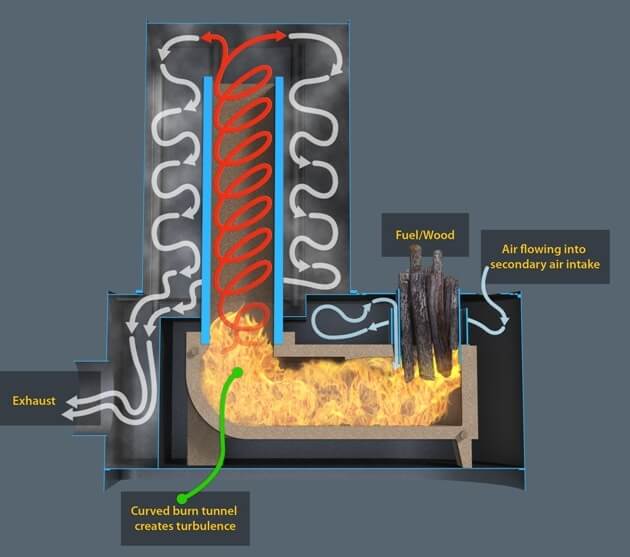

The Dragon Heater

Their Helix stove is a hybrid of a traditional wood stove and a rocket heater. It utilizes a traditional firebox with horizontal feeding of the wood including a glass door for viewing the fire. Then, it uses the turbulence and an internal stack (or secondary burn chamber) from rocket heaters to produce very hot, optimized burns.

Dragon Heater did not complete their planned prototype for the decathalon. Instead they entered with a barrel rocket heater. But they do currently sell an inner chamber (core) kit which can be faced with your choice of refactory material. They intend to have a hybrid wood stove/rocket stove with window on the market in the near future. You will be able to face the hybrid with stone or other refractory material. Lots of examples of potential builds on their website. Castle build kits cost $600 to $1075. See: dragonheaters.com

The importance of turbulence in burning wood.

The fire in the burn tunnel consumes the solids and releases the wood’s volatile compounds. In addition to an insulated combustion zone, the Dragon Burner increases efficiency by insuring that all the exhaust gases are adequately mixed with oxygen from the supply air by creating turbulence.

An 8 inch Derrick build kit costs $1095.

Made in Texas.

www.dragonheaters.com

Intercontinental 2B4W

The 2B4W wood stove designed by Rod Zander is a type of masonry heater that is constructed from recycled materials. It consists of two used steel oil barrels stacked on top of each other, inside the barrels heat is stored in 35 feet of masonry channels which are made up of 3000 pounds of stacked high density firebrick. The recycled barrels are a low-cost solution for the exterior that also provides structural integrity. In a typical masonry stove, 50 percent of the cost is for the facing and the structural material. Rod thought about potential usage in the developing world while designing this stove. Not yet for sale, but hopefully Rod will sell plans in the future.

By Rod Zander of

New England Hearth & Soapstone, Goshen, CT

The company also sells a portable masonry heater.

www.rodzander.com

Ofenbau & Feuerstellen

This is an Austrian Kachelofen (tile stove) with a combustion chamber that received the Eco-label of Austria. The Eco-label sets stringent emissions limits and the highest energy efficiencies known in Europe. This tile stove incorporates this eco-labeled combustion chamber technology for cooking and heating. It achieves low emissions through the way the air streams into the inner body of the stove. Team Captain, Richard Jussel states that “the air streams into the inner body of the stove through a tight baffle or damper situated in the stove’s base, and it branches through controlled slits into the combustion chamber.”

Company: Ofenbau & Feuerstellen

Individually hand built.

Website: www.feuermacher.com

Location: Austria

Tulikivi

– means firestone in Finnish.

Tulikivi entered with their Hiisi 4 hybrid heat-retaining fireplace using soapstone which releases heat more slowly. The Hiisi hybrid can use cord wood or pellets without needing an electric hookup, and it meets the world’s tightest emissions standards. The Tulikivi can also heat water.

89/87% efficiency.

Heats up to 800 sq ft.

$4000. and up.

Made in Finland.

www.tulikivi.com

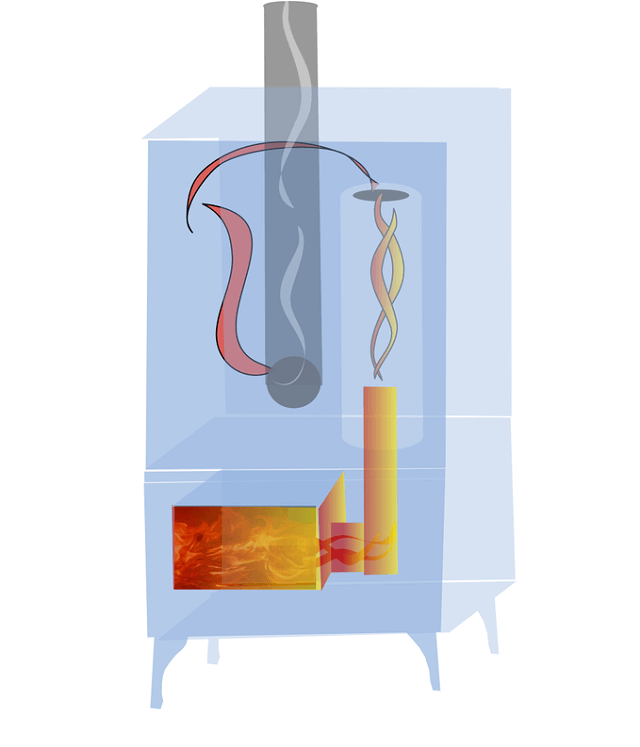

Kimberly Stoves

The Kimberly is portable and can be taken from boat to cabin to RV and into the home. The patented technology of the burn itself is also very different. The bottom flame is kept around 450 to 500 F. That means that the fuel load will slowly release its gases, which are then reburned in an inferno in the top end of the stove. These temperatures often exceed 1500 F, ensuring that the Kimberly has a near smokeless emission. Most stoves today have a single flame path which is elongated by adding secondary combustion air halfway up the path, whereas the Kimberly has two completely separate flames. $3750.

42,500 BTU/hour

Capable of heating up to 1500 square feet.

Burns up to 8 hours on a load of fuel.

Easy install that saves you money.

Use top as a cook top.

American-made stainless steel.

Ten inch diameter! 56 pounds.

See their Katydid stove as well!

Made in Oregon.

www.unforgettablefirellc.com

The Walker Stove

The Walker Stove combines the best features of a rocket mass heater, a masonry heater, and a wood stove. It utilizes the unique burn chamber of a rocket mass heater to completely burn the fuel. The metal radiator, like a traditional wood stove or a rocket mass heater, radiates intense heat to the living space. The flue gases are routed through a masonry mass to allow the slow release of comfortable radiant heat over a long period of time. By coupling such an efficient burn and a fast-acting metal radiator to a system of heated mass-thermal storage, the Walker Stove offers unparalleled warmth and comfort from an amazingly small amount of wood. The combustion core can reach over 2000 degrees F.

The bottom half is so well insulated that it is safe to touch. Woodtock Soapstone bought the prototype Matt entered into the challenge and news is they are communicating on design technique.

Currently built to order. Cores available as well.

Port Angeles, Washingtion State.

Watch Matt’s video:

walkerstoves.com

Read More About The Wood Stove Decathlon

Alliance For Green Heat: forgreenheat.org

- National Geographic: Winning Wood Stove Designs Announced

- The New York Times: Contest Aims for a Cleaner-Burning Wood Stove

- People’s Choice Award from Popular Mechanics Popular Mechanics Finalist Q&A Biomass Magazine

Currently 13 percent of all soot pollution in the United States comes out of wood stove chimneys. So, in early 2014, the EPA released standards that would require all new wood stoves to burn 80 percent cleaner than today’s outdated wood stove pollution standards. The new standards will be slowly implemented over the course of five or more years. All existing stoves are not affected and can remain in use. All pellet stoves are not covered under the new guidelines either. The EPA is just trying to get the wood stove manufacturers to make cleaner, more efficient stoves. The new standards do not affect existing stoves.

love the twinfire double chamber combustion system want one

How much does it cost? How often do you need to put wood on it?

How much does it cost? How often do you need to put wood on it?

What are your thoughts on the Kuma Sequoia wood stove? It has an EPA rating of 84% (putting it at #1 for efficiency).

https://www.kumastoves.com/Store/ProductDetails/sequoia