All around the globe companies and individuals are starting to produce fuel from waste plastic. As only 8% of waste plastic is recycled in the U.S., 15% in Western Europe, and much less in developing countries, this reuse of plastic could potentially keep enormous amounts of plastic out of landfills and out of the oceans.

Why Plastic Waste Is A Problem

Over 500 billion pounds of new plastic is manufactured each year and roughly 33% of that is single use and thrown away. As so little plastic is recycled, we need to reframe plastic waste as an underused resource vs. one that’s destined for the landfill.

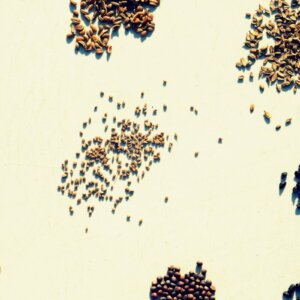

If all plastic waste made it into the landfill, it would surely be mined in the future, but currently all plastic waste does not make it into our landfills. The United Nations estimates plastic accounts for four-fifths of the accumulated garbage in the world’s oceans. We need to stop polluting our oceans with plastic before it is too late, and start collecting all plastics suitable for this new, fairly simple, technology, a technology that is available now.

Image via: coastalcare.org

How Plastic Waste Is Turned Into Fuel

The technology is not overly complicated. plastics are shredded and then heated in an oxygen-free chamber (known as pyrolysis) to about 400 degrees celsius. As the plastics boil, gas is separated out and often reused to fuel the machine itself.

Related Post: Biofuel

The fuel is then distilled and filtered. Because the entire process takes place inside a vacuum and the plastic is melted – not burned, minimal to no resultant toxins are released into the air, as all the gases and or sludge are reused to fuel the machine.

What Plastic Can Be Used?

For this technology, the type of plastic you convert to fuel is important. If you burn pure hydrocarbons, such as polyethylene (PE) and polypropylene (PP), you will produce a fuel that burns fairly clean. But burn PVC, and large amounts of chlorine will corrode the reactor and pollute the environment.

Burning PETE releases oxygen into the oxygen deprived chamber thereby slowing the processing, and PETE recycles efficiently at recycling centers, so it is best to recycle PETE traditionally. HDPE (jugs) and LDPE (bags and films) are basically polyethylene so usable as fuel as well, just slightly more polluting as a thicker heavier fuel is created. But additional processing can turn even HDPE into a clean diesel.

“Polyethylene and polypropylene are pure hydrocarbons, only they are arranged in long chains. If you chop those chains into shorter ones, you get oil, if you chop them even shorter, you get diesel, and if you chop them again, you get gasoline and eventually burnable gas.” www.energeticforum.com

How To Help? Buy A Reusable Water Bottle

The best thing, of course, would be to stop using plastic water bottles completely. We recommend these eco-friendly, reusable water bottles.

- Hydro Flask Insulated Stainless Steel Water Bottle

- Stanley Vacuum Insulated Water Bottle

- Nalgene Tritan Wide Mouth BPA-Free Water Bottle

Machines That Turn Plastic To Fuel

In Niagara Falls, NY, John Bordynuik’s ‘Plastic Eating Monster‘ can even vaporize thick HDPE plastic into a cleaner burning number 2 fuel. Put plastic in one end of the machine and out the other end comes diesel, petroleum distillate, light naphtha and gases such as methane, ethane, butane and propane.

The machine accepts unwashed, unsorted waste plastics, composites and commingled materials and returns about 1 gallon of fuel from 8.3 pounds of plastic. And the processor uses its own off-gases as fuel, therefore using minimal energy to run the machine. John has two massive steel processors up and running, with financing secured for three more to be built in the very near future.

In the Philippines, Poly-Green Technology and Resources Inc. was started by Jayme Navarro whose sister asked him to come up with a way to recycle plastic bags. A plant is being built that will produce 5,000 kilos of fuel per day. www.polygreen.com.ph

Related Post: In a Plastic World, Recycling Ain’t What It Used to Be

Plastic to Fuel Power Plants

Cynar in the UK likes to call their product ‘End of Life Plastic to Diesel’ or ELPD. Their technology converts mixed Waste Plastics into synthetic fuels that are cleaner, low in sulphur and in the case of the diesel, a higher cetane than generic diesel fuel.

They have two plants running in Spain. Each Cynar plant can process up to 20 tons of End of Life Plastic per day, producing 5,000 gallons (19,000 litres) of high quality liquid fuels at a conversion rate of 95%.

Cynar will be supplying Jeremy Rowsell, a British insurance industry executive who lives in Australia, with all the plastic waste fuel he needs to fly a single-engine Cessna from Sydney to London this winter. Fuel will be in place at about 10 locations along the 10,500-mile route. The solo journey dubbed ‘On Wings of Waste‘ is intended to heighten awareness of this new fuel.

The Future of Plastic to Fuel

Of course, it would be the best if there were widespread environmentally friendly plastics in use, but in the meantime, recycling existing plastics into fuel would keep the plastics out of our waterways. This process is also excellent for difficult to recycle PP and PE plastics like bottle caps, appliance plastics, nursery planters and dirty plastics such as meat wrappings. This process is not suitable for PVC or polystyrene (styrofoam). This technology could also reduce carting issues, as companies that deal with plastic waste could build mini-burners on location. I am ready for a plastic collection can on my corner, how about you?

A Cynar video can be found here: cynarplc.com

Many questions as to which technology is the most efficient and least polluting…

Plastic to Fuel Companies

Japan. Sells International: e-n-ergy.com

UK: Cynar produces a synthetic fuel suitable for all internal combustion engines: cynarplc.com

Atalanta, GA: Nexus Fuels

Washington, DC: envion.com. Boasts easy installation, high efficiency, no second-time pollution. Plant converts 6,000 tons of plastic into nearly a million barrels yearly.

Circle Pines, MN and International: polymerenergy.com

They have a modular unit that produces 775 liters of fuel for every ton of plastic waste processed. System capacity is rated at 185 tons per month.

New York/Canada: JBI, Inc. plastic2oil.com

20-ton processor, 4,000 lbs. of plastic feedstock per machine per hour.

Phillipines: polygreen.com.

5,000 kilos of fuel per day.

Hong Kong: Ecotech Recycling Social Enterprise. Prototype machine can process three tons of plastic waste into 1,000 liters of fuel oil per day.

Las Vegas, NV: general@quadraprojects.net

Plastic to Fuel Resources

UNEP Policy Brief on Plastic Waste: unep.org

Northeastern University turns plastic waste into energy to drive generators: phys.org

DIY for under $800.: energeticforum.com

Peswiki Plastic and Energy page: peswiki.com

This homemade device converts around 25 kg of shredded plastic into 24 litres of diesel in 4 hours. emuprim.lv

I am currently doing Chemical Engineering from Dawood University of Engineering and Technology, Karachi. I have a team of three members and desire to make a project on the same thing i.e. Waste Plastic to Oil. We are nearly amateur and can just desire for the time being to have a deep research on the system. For that we need to get ourself affiliated with your group and to have a sound and profound knowledge on the focal process. I shall be highly grateful to you if you aid me in this regard mentioned in the message.

Have a great day.

Thanks. Muhammad Nashit Rizwan, B.E. (Chemical Engineer).

hey 🙂 i want some help on the same project please contact me ASAP . 03356281422 its my number please 🙂

we have developed commercial running plant from waste plastic to fuel ie petrol and diesel

8712000900 call us

visit our blog

raajfuels.blogspot.in/

I am also interested in this project, I watched a lot of videos but I stil don’t understand how the production of petrol and diseal differs, the process looks the same, how do I insure that what I am producing petrol not diseal.

I am from Botswana in Africa, if possible contact me via Whatsup @ +26774574807

Hello

We are the well reputed company in Belgium from 25 years supplying Gasoline.We are interested in the converting the Fuel through Plastic or trash and want to do the same project here.

Could you please give us all the quotations(cost to develop the plant) so that we can work further.

We will be greatful to you.

Kirti

Dear Sir/Madam,

I need consultancy to start small/medium size Plastic waste to Bio fuel industry in India,

Please let us know the machinery required and initial investment etc., at the earliest

With Regards,

K Sudhakar

Respected Sir,

I want to make Fuel/Gas/Energy from Wastage Materials like Paper, Garbage, Plastic whatever we have throw out/use less materials.

So, Kindly suggest a Machinery regarding it.

Hope to hear soon from u.

Kind Regards,

Padia Praful

Gujarat-India

Mobile No.091 98791 28374.

How can I have one of these?

Respected Sir,

I want to make Fuel from Wastage Plastic whatever we have throw out/use less materials.

So, Kindly suggest a Machinery & setup cost regarding it.

Hope to hear soon from u.

Kind Regards,

Ranjan kumar

mechanical engineer

mob no :- 8591583855

Dear sir…salam alikum

We need to make Fuel/Gas/Energy from Wastage Materials like Paper, Garbage, Plastic whatever we have throw out/use less materials. Could you Kindly suggest a Machinery to fulfil this criteria.

Thank you for your time.

Ali Nadhim -Iraq

Email: alinadhim2003@yahoo.com

sir,

to removal of the oxygen ,why do not use the material of oxygen scavenger are used? the material like iron powder and also the Nacl are thermally stable,

Sir/madam,

With due respect i would like to requist your good self to kindly suggest me the machinery needed for converting plastic waste into usable fuel including set up cost and prodution process.

Thanking you

With regard

Prabin Rai

Bhutan

+97517753068

Email: pra.hotg@gmail.com

Sir/madam,

With due respect i would like to requist your good self to kindly suggest me the machinery needed for converting plastic waste into usable fuel including set up cost and prodution process.

Thanking you

With regard

Prabin Rai

Bhutan

+97517753068

Respected Sir,

I want to make Fuel from Wastage Plastic whatever we have throw out/use less materials. So, Kindly suggest a Machinery & setup cost regarding it. Hope to hear soon from u. Kind Regards, Rajendra singh rana

mob no :- 9111147459

I want to start of own business so i fell that this is very good option for me . so i hope that please tell me about this training and machine where i purchase it .

Hi there

I’m trying to find someone to help me get onto the right track to cleaning up plastic around Indonesia. Now I’m looking at starting the same System as the Philippines Has started would love to know how or who you would go through to start looking into this. Thanks.

I am very much impressed by how plastic can be made into fuel. I am writing from Ghana. I don’t want to set up such a means here in Ghana. I rather want to be a supplier of any plastic waste you would require. I mean any quantity.

Our main problem in Ghana is uncontrollable littering. Education to stop that is ongoing but I think partnering with such a company to supply plastic waste would help save us from such mess.

please do contact me through my e-mail above and let’s do business.

Spear Transpower,

242,Pushpak Estate,

Nikatube compound,

Phase-1,Vatva G.I.D.C.,

Ahmedabad-382445,

16th March 2016.

Dear Sir,

Good day,

We would like to take this opportunity to introduce “SPEAR TRANSPOWER“,as one of the Plastic Ancillary manufacture in Gujarat ,Our Vision to reach the acme of perfection by products that are not only innovative but also high in quality.We are dedicated to achieving the milestones as well as keeping our customer completely satisfied .we are customer focused enterprise committed to excellence, service, reliability, integrity and high quality. We have been successful at our procurement mandates because of our:

Ability to deliver our goods in a timely manner

Ability to deliver quality goods to our clients’ specifications

Competent Team and professional service.

Spear Transpower are manufacturer of Hot air dryer,Hopper Loader,Dehumidifier Air Dryer,Air & Water Chiller,Granulator ,Volumatric dosing,Gravimeter Dosing, in Gujarat. We are also having wide Product Range like Silo , storage Bin, Regenerative blower,control card for plastic ancillary,high temp hose, anti static. PVC pipe,Pu pipe.

If you have any inquiry please feel free to contact us. It would be highly appreciated if you could register our company name in your approved vendor list, for relevant business opportunities, so as to render our services to your esteemedselves in the foreseeable future.

We also offer to you our OEM best rate, if you want to sell our product by your company name, we also provide you our all product with your logo & your company name.

We would like to thank you for the time that you have taken in order to go through this letter.

We would like to do spares business with your organization.

Kindly give us one opportunity.

With Warm Regards

Shobimon M.J.

Mobile:-7069466116

Spear Transpower

speartranspower@gmail.com

Amazing piece of technology. I would like to set up the system in Kenya. Kindly email me the cost of the machinery and the associated installation costs. Much thanks.

ondiekhann@gmail.com

Amazing piece of technology. we would like to set up the system in Tanazania. Kindly email me the cost of the machinery and the associated installation costs with all details of process. Much thanks.

Sir/madam,

With due respect i would like to request you to kindly suggest me the machinery needed for converting plastic waste into usable fuel including set up cost and production process.

looking forward to hear from you.

Thanking you

Name:mutema wycliffe

civil engineer

Phone:+254700044762

e-mail:wyclic14@gmail.com

hi,

Please could you get in touch with me as i would like to purchase your equipment .

Regards

Hi can you send me plans or drawings or cost of machine

I am busy starting up various projects of this nature in Southern Africa. We manufacture plants of various sizes and capacities, from 120 liters per day to 2000 liters per day. Contact me for prices or to fund and get involved in projects we are starting up. You can find me on the web, my company name is Green Living For Freedom And Sustainability and we want to change the world for the better 🙂

More meneer van Rensburg,

Ek spook al vir 18 mnde om diesel uit plastiek te maak.Ek kry verskillende resultate en weet ook nie wat se brandstof dit is nie.

Dear Nikodemis,

I am Johannes Rogaar and interested to install a small scale machine that converts plastic into fuel. I am curious whether we can work together on this opportunity.

Can you please contact me on +41793098578 or email johannes.rogaar@givaudan.com

Many thanks, Johannes

Sir, I appreciate the time you take out of your schedule to help us. I am interested in setting up a plant facility for recycling of waste plastic into fuel in Mumbai (India).

Please provide us the details regarding the plant size and capacity, machine requirements with their specifications, area required, manpower capital investment and such other details that may be necessary to evaluate our project.

Please provide us with a suitable project report that can help us understand better the financial details and help in executing our plans at the earliest.

Thank you.

With Regards,

Annup borrge

e-mail: annupborrge@outlook.com,

sir,

If you have started processing please contact us for waste

Interesado en el tema

who wrote this article

I am a PhD. student in Michael okpara University of Agriculture Umudike, Abia State Nigeria. I working on this plant (waste plastic pyrolysis plant), for my Phd program.

I would like you to send me your plant data, so that I can use it for my project analysis.

Contact: igwejohneze4@gmail.com

Thanks.

Dear sir, i would like to know how much it will cost to get a local processing plant that turns plastic into fuel or oil. kindly also give me quotations for various sizes. The maim aim of my interest in this project is to see how i can help eradicate huge waste from my country Nigeria and also convert them to green energy. i humbly await your response

How can we key in into this technology and others.

i am student of m phil it is good to produce energy from plastic waste… could you plz help me that how we can control tje emmisions of dangerous gases??? or during this process various gases are produced these gases have any impact during the whole process??

Hi, This is Clover from Huayin Group, China, which specialized in developing, manufacturing and sales of waste plastic rubber tire recycling equipment. Welcome to contacting me and visiting our factory.

Clover

Huayin Group

Mobile/Skype/What’s App: +8618137820062

E-mail: clover@huayinrecycling.com

Website: http://www.huayinrecycling.com

Dear

With respected. I’m a student of BS chemical engineering and i have final year project ‘conversion of waste plastic into fuel by pyrolysis’ .I need some help regarding composition of flue gases in cyclone separator and inlet of distillation column.

Waiting for your kind consideration

Thanks

I am currently doing Environmental Science from Kwame Nkrumah University

of Science and Technology, Ghana. I have a team who desire to make a project on turning plastic waste into diesel. We are nearly amateur and can just desire for

the time being to have a deep research on the system. For that we

need to get ourself affiliated with your group and to have a sound

and profound knowledge on the focal process. I shall be highly

grateful to you if you aid me in this regard mentioned in the

message.

Kindly send me any information through my email above.

Thank you.

With due respect sir, regarding my final year project, which is related to the topic above ‘Design of pyrolysis plant to produce 100,000 tons per year from waste plastic’ I need to have the full knowledge about the project, in this case, i will like if you can send to me the material that contain the FLOWSHEET DIAGRAM, METHOD OF OPERATION, THE ESTIMATED RESULT etc. In my email address….pchikaodili@gmail.com

Any info on this technology and how to start healing our enviorment would be greatly appreciated. I am from Mexico and greatly admire your efforts and hopes.

Thank you

Hello dear, i would like to buy, tell me, please how much the price? And how we can start ?

Having trouble with the links to companies. Most are saying they are expired web domains.

Please can you send me more information cost and budgetfor a plant that can produce 5000lts to 10000lts a day . I would like to set up a plant

I have completed M. Tech. in Plastic Engineering. I am also interested in this field to work.If you have any option please contact me.

Have a good day

Dear Sir/Madam,

I need consultancy to start small/medium size Plastic waste to Bio fuel industry in India,

Please let us know the machinery required and initial investment etc., at the earliest

With Regards,

D.Nagaraju

hi myself shoaib manyar(Mechanical Engineer). i just read the concept and i just loved it.can u please give me information about the requirements of plant means which machineries are required.and how much it will cost????

Email- shoaib.manyar0@gmail.com

Mobile-7420088066

Respected sir,

I’m continuing the post graduation on the topic of ballistics.

I’m very much interested to work on such project like PLASTICS TO FUEL. It is definitely a revolutionary idea. The above article described how to make fuel like gasoline from PE & PP. It attracted me the most.

Could you please provide me all the information about this process.

Dear Sir/Madam,

I need consultancy to start small/medium size Plastic waste to Bio fuel industry in India,

Please let us know the machinery required and initial investment etc., at the earliest

With Regards,

KINTHALI SAI KISHORE

Hello, found this post while researching plastic to fuels and it’s a wonderful collection of information. Any chance you’d be able to update it? several of the companies seem to have gone out of business and even the DIY link is gone as well unfortunately.

The real question here is whether the output is greater than the input. If the energy in the fuel output is less than the electricity used to heat the system, it’s a net loss and not worth doing. I suppose if you ran it off of solar that would not be true, but if you run it off of electricity (unless that was nuclear) you are just moving backward.