In most homes and apartments, cooking takes place on a stove, in an oven, or, on those nights when you’re just too tired to think, in the microwave. But these aren’t the only ways to prepare a meal, and they’re certainly not the most energy efficient.

You know those hot summer days when you can see heat waves rising from the sidewalk, and people say things like “that sun’s hot enough to fry an egg”? Well, there’s more wisdom to that statement than you might think.

Solar ovens are simple devices that capture heat from the sun with a reflective surface that’s angled or curved towards a cooking pot. Because they can be easily made from cheap materials like scrap cardboard and tinfoil, they are widely used in areas of the world where trees and fossil fuel are scarce or expensive. Once made, they can be used to cook food and boil water in a reasonable amount of time for absolutely no cost.

When you think of solar, you probably think of solar PV panels, but solar energy comes to Earth in both heat and light. Solar panel prices are cost-competitive with other electricity generation options because solar panels have become very efficient at turning light into electricity and the savings are often much greater than the cost.

In the end, solar panels are a great way to reduce your electricity bill, but you don’t have to cook with electricity. Solar cookers capture solar energy’s heat and use that heat to cook your food. You don’t really have to consider “the cost of solar panels” versus “the cost of solar cookers” — you can get both … or make them! Many of the advantages of solar energy are the same for both types of solar.

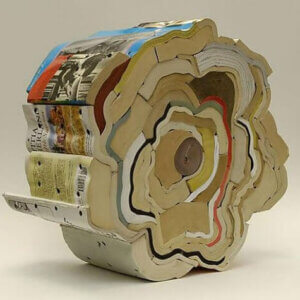

Cooking with solar energy is just one of the many topics featured in Eric Smith’s new book, DIY Solar Projects: How to Put the Sun to Work in Your Home.

Smith was nice enough to let us publish a few excerpts from this book so that we can learn more about how to cook with the clean energy of the sun instead of coal-fired electricity or natural gas.

On the next few pages, you’ll find easy to follow directions for building your own solar oven. Then later this week, we’ll feature some of Smith’s favorite tips for cooking on a solar powered stove!

Tools and Materials Needed

- Straightedge

- Circular saw

- Jigsaw or plunge router

- Tape measure

- Drill/driver with bits

- Speed square

- Stapler

- Eye and ear protection

- #8 countersink bit

- ¾” × 4 × 8-ft. BC or better plywood

- 2 × 12 × 8-ft. SPF SolaRefle× foil or heavy-duty aluminum foil

- 1⅝ and 2½” deck screws

- Clear silicone caulk

- Contact cement, or white glue and brush, optional

- Mid-size black metal pot with glass top

- Wire rack

- ¼ × 17¼ × 17¼” tempered glass

- No-bore glass lid pulls (Rockler item no. 29132)

- ¼ × 2″ hanger bolts with large fender washers and wingnuts

Cutting List

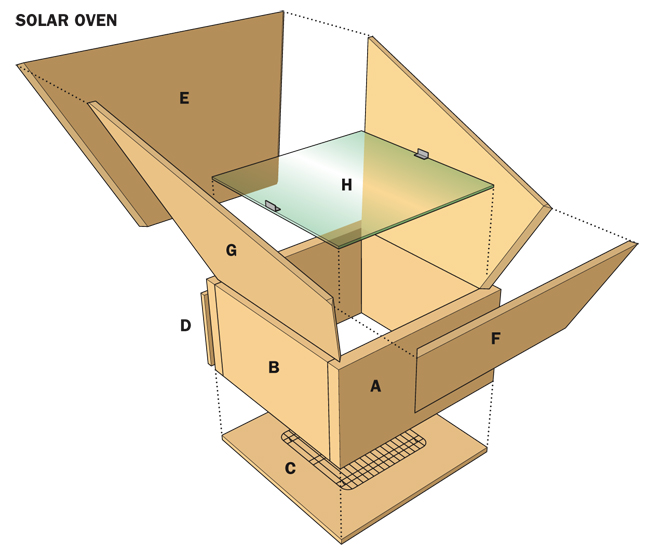

Key Number Dimension Part Material

A 2 1½ × 11¼ × 19″ Base SPF

B 2 1½ × 11¼ × 16″ Base SPF

C 1 ¾ × 19 × 19″ Bottom Plywood

D 1 ¾ × 10 × 17″ Adjustable leg Plywood

E 1 ¾ × 20 × 33¾” Back Plywood

F 1 ¾ × 10 × 25¼” Front Plywood

G 2 ¾ × 20 × 31¼” Sides Plywood

H 1 ¼ × 17¼ × 17¼” Cover Tempered glass

>>UP NEXT: How To Build A Solar Oven – Steps 1 – 7

How To Build A Solar Oven: Steps 1 -7

1. Cut the four 2 × 12 base pieces to length according to the cutting list. Arrange the base parts on a flat work surface and clamp them together in the correct orientation. Check with a carpenter’s square and adjust the parts as needed. Then drill pilot holes and fasten the pieces together with 2½” deck screws.

2. Lay a 4 × 8-ft. sheet of plywood on the worksurface with the better side facing up. Select a good grade of ¾” plywood (we used BC) or you’re likely to have issues with parts warping, and you’ll find it difficult to drive screws into the edge grain of the plywood. Mark and cut the 19 × 19″ bottom piece first. Rest the full sheet of plywood on a couple of old 2 × 4s—you can cut through them as you make your cuts without any need to move them out of the way.

3. To create the panels that form the reflector you’ll need to make beveled cuts on the bottom and sides so the panels fit together squarely. With the best side of the plywood facing up, mark two 20″ x 76″ long pieces, measuring from the two factory edges so the waste will be in the middle. Set your circular saw base to 22½°, then cut along the line you drew at 20″ (20″ is the long side of the bevel). Cut the other piece starting from the opposite end of the plywood. You should end up with two mirror image pieces.

4. Re-set your saw base so it’s flat, then cut each 20″-wide panel in half so you have four 20 x 38″ panels, each with one beveled 38″ edge. With the beveled edge facing up and closest to you, draw a centerline at 18″ on each panel, then make marks on the beveled edges at 8″ on both sides of the centerline. Position a speed square so it pivots at the 8″ mark, then rotate the speed square away from the centerline until the 22½° mark on the speed square meets the top of the beveled edge. Draw a line along the speed square as shown, then use a straightedge to extend the line to the other edge (the factory edge) of the plywood. Repeat at the other 8″ mark, flipping the speed square and rotating it away from the centerline so the lines create a flat-topped triangle. Set the base of your circular saw at 40°, then cut along the angled lines (although it seems incorrect, 40° is the angle required to form a square corner when the pieces are assembled). Mark and cut the remaining three panels in the same fashion.

5. Finish cutting the reflector parts to final size and shape. TIP: Clamping or holding smaller parts for cutting can be tricky. Here is a useful trick: After you’ve laid out your cutting lines, set the workpiece onto a pair of old 2 × 4s. Tack the workpieces to the 2 × 4s with finish nails, ideally driven into the waste area of the panels. Keep the nails at least a couple of inches from any cutting line. Set your saw so the cutting depth is about ¼” more than the thickness of the workpiece and then make your cuts.

6. Assemble the reflector. Brace two of the reflector sides against a square piece of scrap plywood clamped to the work surface, then join the edges with screws driven into countersunk pilot holes. Repeat for the other two pieces, then join the two halves together with four screws at each corner, completing the reflector. The bottom edges should be aligned. The top edges won’t match perfectly, so sand them smooth.

7. Make the adjustable leg, which contains parallel slots so the leg can move up and down over a pair of hanger bolts, raising and lowering the angle of the cooker so you can take full advantage of the direction of the sun’s rays. Outline the slots in the adjustable leg of the oven so they are ⅜” wide (or slightly wider than your hanger bolt shafts). Locate a slot 2″ from each edge of the adjustable leg. The slots should stop and start 2″ from the top and bottom edges. Cut the slots with a jigsaw or a plunge router.

>>UP NEXT: How To Build A Solar Oven, Steps 7 -13

How To Build A Solar Oven: Steps 7 – 13

7. Make the adjustable leg, which contains parallel slots so the leg can move up and down over a pair of hanger bolts, raising and lowering the angle of the cooker so you can take full advantage of the direction of the sun’s rays. Outline the slots in the adjustable leg of the oven so they are ⅜” wide (or slightly wider than your hanger bolt shafts). Locate a slot 2″ from each edge of the adjustable leg. The slots should stop and start 2″ from the top and bottom edges. Cut the slots with a jigsaw or a plunge router.

8. Screw the base and the plywood bottom together. Set the adjustable leg against one side of the base, then drill guide holes and install the hanger bolts so they will align with the slots. The centers of the bolts should be at the same height: roughly 2½” up from the bottom of the box. Use large fender washers and wingnuts to lock the adjustable leg in position.

9. Fasten the reflector to the base with countersunk 2½” screws. Angle the drill bit slightly as you drill to avoid breaking the plywood edge. Use two screws per side.

10. Cut pieces of reflective sheeting to fit the sides of the reflector as well as the base. You can use heavy-duty aluminum foil, but for a sturdier option try solar foil. The product seen here is essentially polyethylene tarp material with a reflective aluminum surface. Make sure to cut the pieces large enough so they overlap the edges and can be easily attached.

11. Glue the reflective sheeting inside the base and reflector, overlapping the corners so all bare wood is covered. Use contact cement or silicone caulk to adhere solar foil, and staple the edges to reinforce the glue; use diluted white glue with a paint brush instead of contact cement if you’re using aluminum foil. Pull or smooth out the reflective material as much as possible; the smoother the surface is, the better it will reflect light.

12. Take measurements to double-check the glass lid size. Ideally, the lid will fit in so it comes to rest about 1″ above the top opening of the box. As shown here, a ¼ × 17 × 17″ piece of tempered glass fits just right. Be sure to order glass with polished edges. You can also just use a clear plastic oven bag instead of the glass. Either will trap heat and speed up the cooking.

13. Caulk the joint between the angled top and the base with clear, 100% silicone caulk. Set a wire rack inside the oven to keep the cooking pot slightly elevated and allow airflow beneath it.

To see more of the beautiful illustrations that go along with this project, check out Eric Smith’s new book, DIY Solar Projects: How to Put the Sun to Work in Your Home.

Leave a Reply