All around the globe companies and individuals are starting to produce fuel from waste plastic. As only 8% of waste plastic is recycled in the U.S., 15% in Western Europe, and much less in developing countries, this reuse of plastic could potentially keep enormous amounts of plastic out of landfills and out of the oceans.

Why Plastic Waste Is A Problem

Over 500 billion pounds of new plastic is manufactured each year and roughly 33% of that is single use and thrown away. As so little plastic is recycled, we need to reframe plastic waste as an underused resource vs. one that’s destined for the landfill.

If all plastic waste made it into the landfill, it would surely be mined in the future, but currently all plastic waste does not make it into our landfills. The United Nations estimates plastic accounts for four-fifths of the accumulated garbage in the world’s oceans. We need to stop polluting our oceans with plastic before it is too late, and start collecting all plastics suitable for this new, fairly simple, technology, a technology that is available now.

Image via: coastalcare.org

How Plastic Waste Is Turned Into Fuel

The technology is not overly complicated. plastics are shredded and then heated in an oxygen-free chamber (known as pyrolysis) to about 400 degrees celsius. As the plastics boil, gas is separated out and often reused to fuel the machine itself.

Related Post: Biofuel

The fuel is then distilled and filtered. Because the entire process takes place inside a vacuum and the plastic is melted – not burned, minimal to no resultant toxins are released into the air, as all the gases and or sludge are reused to fuel the machine.

What Plastic Can Be Used?

For this technology, the type of plastic you convert to fuel is important. If you burn pure hydrocarbons, such as polyethylene (PE) and polypropylene (PP), you will produce a fuel that burns fairly clean. But burn PVC, and large amounts of chlorine will corrode the reactor and pollute the environment.

Burning PETE releases oxygen into the oxygen deprived chamber thereby slowing the processing, and PETE recycles efficiently at recycling centers, so it is best to recycle PETE traditionally. HDPE (jugs) and LDPE (bags and films) are basically polyethylene so usable as fuel as well, just slightly more polluting as a thicker heavier fuel is created. But additional processing can turn even HDPE into a clean diesel.

“Polyethylene and polypropylene are pure hydrocarbons, only they are arranged in long chains. If you chop those chains into shorter ones, you get oil, if you chop them even shorter, you get diesel, and if you chop them again, you get gasoline and eventually burnable gas.” www.energeticforum.com

How To Help? Buy A Reusable Water Bottle

The best thing, of course, would be to stop using plastic water bottles completely. We recommend these eco-friendly, reusable water bottles.

- Hydro Flask Insulated Stainless Steel Water Bottle

- Stanley Vacuum Insulated Water Bottle

- Nalgene Tritan Wide Mouth BPA-Free Water Bottle

Machines That Turn Plastic To Fuel

In Niagara Falls, NY, John Bordynuik’s ‘Plastic Eating Monster‘ can even vaporize thick HDPE plastic into a cleaner burning number 2 fuel. Put plastic in one end of the machine and out the other end comes diesel, petroleum distillate, light naphtha and gases such as methane, ethane, butane and propane.

The machine accepts unwashed, unsorted waste plastics, composites and commingled materials and returns about 1 gallon of fuel from 8.3 pounds of plastic. And the processor uses its own off-gases as fuel, therefore using minimal energy to run the machine. John has two massive steel processors up and running, with financing secured for three more to be built in the very near future.

In the Philippines, Poly-Green Technology and Resources Inc. was started by Jayme Navarro whose sister asked him to come up with a way to recycle plastic bags. A plant is being built that will produce 5,000 kilos of fuel per day. www.polygreen.com.ph

Related Post: In a Plastic World, Recycling Ain’t What It Used to Be

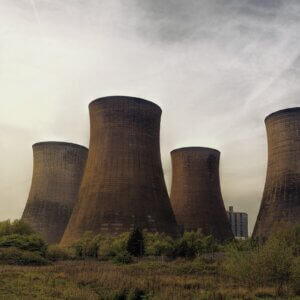

Plastic to Fuel Power Plants

Cynar in the UK likes to call their product ‘End of Life Plastic to Diesel’ or ELPD. Their technology converts mixed Waste Plastics into synthetic fuels that are cleaner, low in sulphur and in the case of the diesel, a higher cetane than generic diesel fuel.

They have two plants running in Spain. Each Cynar plant can process up to 20 tons of End of Life Plastic per day, producing 5,000 gallons (19,000 litres) of high quality liquid fuels at a conversion rate of 95%.

Cynar will be supplying Jeremy Rowsell, a British insurance industry executive who lives in Australia, with all the plastic waste fuel he needs to fly a single-engine Cessna from Sydney to London this winter. Fuel will be in place at about 10 locations along the 10,500-mile route. The solo journey dubbed ‘On Wings of Waste‘ is intended to heighten awareness of this new fuel.

The Future of Plastic to Fuel

Of course, it would be the best if there were widespread environmentally friendly plastics in use, but in the meantime, recycling existing plastics into fuel would keep the plastics out of our waterways. This process is also excellent for difficult to recycle PP and PE plastics like bottle caps, appliance plastics, nursery planters and dirty plastics such as meat wrappings. This process is not suitable for PVC or polystyrene (styrofoam). This technology could also reduce carting issues, as companies that deal with plastic waste could build mini-burners on location. I am ready for a plastic collection can on my corner, how about you?

A Cynar video can be found here: cynarplc.com

Many questions as to which technology is the most efficient and least polluting…

Plastic to Fuel Companies

Japan. Sells International: e-n-ergy.com

UK: Cynar produces a synthetic fuel suitable for all internal combustion engines: cynarplc.com

Atalanta, GA: Nexus Fuels

Washington, DC: envion.com. Boasts easy installation, high efficiency, no second-time pollution. Plant converts 6,000 tons of plastic into nearly a million barrels yearly.

Circle Pines, MN and International: polymerenergy.com

They have a modular unit that produces 775 liters of fuel for every ton of plastic waste processed. System capacity is rated at 185 tons per month.

New York/Canada: JBI, Inc. plastic2oil.com

20-ton processor, 4,000 lbs. of plastic feedstock per machine per hour.

Phillipines: polygreen.com.

5,000 kilos of fuel per day.

Hong Kong: Ecotech Recycling Social Enterprise. Prototype machine can process three tons of plastic waste into 1,000 liters of fuel oil per day.

Las Vegas, NV: general@quadraprojects.net

Plastic to Fuel Resources

UNEP Policy Brief on Plastic Waste: unep.org

Northeastern University turns plastic waste into energy to drive generators: phys.org

DIY for under $800.: energeticforum.com

Peswiki Plastic and Energy page: peswiki.com

This homemade device converts around 25 kg of shredded plastic into 24 litres of diesel in 4 hours. emuprim.lv

hi

please said bag making machine that work with gas energy .

sincerly

dear sir/madm i want the petrol making machine with use of plastic

Hi Dear

I would like to know about the cost and other details on above method.

my mail id sridhaar@yahoo.com

Please respond

Thank you

hello this is George again, thanks for your reply, think i will use a local fabricator, but then i am requesting you to send me the detailed information required in the fabrication process, because when i look the picture of this machine, it has got some technical equipments like digital box, i don’t where its for cooling, temperature or pressure.

i would like to know if at all i can make this oil in the same way local brew is made using metallic drums and thirdly is the out which is got out of the precess similar to furnace oil that is used in boilers and steel rolling furnaces

Is there anybody that can supply me with a machine that can process old tyres and waste plastic into diesel. I want about

10 thousand litres a day of clean pure ready to use diesel.

Please if you can help send me a mail. ignus60@gmail.com

I am very much interested to put htis project. plz contact on my e-mail Id. Thanks

hello all,i am kaja from karur tamilnadu india.i am advance type plastic pyrolysis plant(plastic to diesel)manufacturer.municipal solid waste like used carry bags,oil pouchs,shampoo pouchs,milk covers,biscuts&food covers,etc.converting to diesel.high yield(per kg waste plastic converting to 700-ml diesel)available in three size.300-lt per day,500-lt per day,1000-lt per day.if you interested person contact me 08903517768,email:kkmoini@yahoo.co.in and get more information.

Interested to buy a tyres and plastic converter to diesel need info please.

contact for Plant

HEERA ENERGY SYSTEM

By Its Constituted Attorny

SHERRY HENRY

Pyrolysis Plant Business Division.

Mob: +91-7389244224

Please may i no the price of the machine which converts plastic waste into diesel.

Email:amayisi2011@gmail.com

Phone:233-0244710845

Country:Ghana.

how could you distill and filter the boiled plastic,which chemicals are used in that process..?

WE ARE INTERESTED IN YOUR SYNTHETIC FUEL PLANT AND MACHINERY, AND WE WOULD LIKE TO HAVE MORE DETAILS ON WASTE PLASTIC {POLYETHYLENE PP} WASTE CONVERSION TO DIESEL, GASOLINE AND KEROSINE

I want to know how the homemade device was made. We want to make it as our investigatory project.

Thanks if you will share.

There is a company that has been converting plastic into spec fuel for the past 5 years in upsate New York. Fully permitted by the state of New York to operate the production facility. Search for Plastic2oil.

please i want to know the experimental information and mathematical calculation for 1 kg device because i want to try this experiment in my country .

please send to me at : nazeeh.albokary@hotmail.com

I want to try this in India , Please inform me about the whole experiment . or some contact who can give me in india .

Hi my name is Lisa. I represent JL Ag Plastic Recycling. We are a recycling company located in the center of Washington State. We are 1 of very few recyclers of plastic in our state. And the only ones doing all ag plastic at this time. In our state Silage is one of the main ways to feed our animals. That is grain, hay, fruit and veggies in extremely large plastic bag. The peel away the bag as they feed. As far as we know we are the only company that will recycle this form of plastic. It is LDPE black and white film. This is film that is as long as a football field in some cases. And 1/2 as wide. With no one but us trying to do something with it. I was thinking this would be a prime plastic to start with. We can corner the market on this and show the world your machine. There are not many facilities in Washington State to recycle plastics. And we are a mostly farming State or large factories which all get products in plastic wrap of some kind. I believe that a facility to get plastic to a recycled form could be profitable in our area. Please let me know if you are interested in this. SINCERELY, Lisa

I am very much interested this project in India. please contact me on my mail with all details.

Good day

I am a piggery manager in South Africa and I would very much like to obtain one of your inventions.

we have a lot of chemical plastic drums that are getting more and more by the day. Please help!! if you can contact me via e-mail ( juanjansenvanvuuren93@gmail.com ) I would much appreciate it sothat we can discuss me purchasing one of these machines.

Greetings from SA

Juan

hi

i am arun and i am a graduate ,as we see people in day to day needs plastic is playing a big role …which can be a big harm to environment ,your invention makes the society a big help to make use of plastic wastage .If you can contact me through mail ,it would be helpful.

(kannuri.arun@gmail.com)

thanking you

Arun

this is good favour to our environment. I am interested in setting up unit. Please contact me at klengineers9@gmail.com.

this is good favour to our environment. I am interested in setting up unit. Please contact me at klengineers9@gmail.com.

It is good

i want to buy this machine in india if interesting contact me

sir i am intrested in installing this plant

we are making this for our chemical engineering design project and we’ve got a problem. how can we dilute petroleum from pyrolysis? thanks!

i want to buy the machine

if intrested please contact me at

mob. no. 9420595106, 8796147677

I m interested to buy this machine for making fuel from plastic waste in India and what is the price of this machine

very nice process in future he was staying a world GDP,………………………….

My name is banji, im a nigerian pls i wld love to get more information about price, capacity and weight of the differennt conversion machines available in your companies for immediate business. If you are interested you can contact me on 2348135256292 or email me kehindeadetula@gmail.com. Thanks

I have built this machine. Check us up at http://www.affordableenergysolutions.com.ng

Dear Sir,

Greetings of the day.

I am working on plastic and tire pyrolysis since last 6 years. I am exploring all the possibilities.

I have visited many tire pyro plants, but I was not satisfied with the practice. Hence, I decided to work on a continuous system.

I worked for the drawing first, in 2010. In 2011, I registered a patent. I fabricated a plant as per the idea, and conducted number of trials. I developed a suitable catalyst also.

After a long path, I overcame all the problems and in last year, I could touch the glory.

There are 2 models. One was successfully running at Sangli, My place (Maharashtra). I had another easy and compact, efficient model drawing. I fabricated the same at Bhivadi, 75 Kms from Delhi.

This new model worked very efficiently and to my mark of satisfaction. This model has no bar of capacity, and raw material. We can built to any desired tune. Being a continuous system, even for 48 TPD (Input) the machine becomes 2 MT per hour.

With the help of catalyst, we can feed mixture of raw materials and get wax free oil.

As we spoke about the sulfur in TPO (Tire Oil), The sulfur is present in tires, that comes out with dis-agreeable odor. I had a demand from Lubbok Carbon LLP, to reduce the sulfur. This was a special requirement from a copper foundry.

I worked on the system, as much as I could, the conclusions are as here:

1. We can reduce 50% sulfur by adding the specially developed catalyst at the time of feed, sulfur will be fixed in carbon.

2. We can refine the produced oil to any extent. We get sulfur out.

The refine of oil is costlier than adding catalyst.

so

3. I suggested them to add The catalyst and run the oil (Gaseous and hot form, before condensation) through a molecular sieve or iron shriving (scrap).

The third method gave better results. the Sulfur reduced by 81.7%.

but I got very less time to work on the system, unfortunately the crude oil prices came down and the Lubbok got closed due to poor economics.

i am very sure, if I get some more time and free hand, I can reduce the sulfur and get consistent results. In fact, I got only one trial at Lubbok carbon LLP. after that they closed the plant.

I am little more interested in plastic pyrolysis. The plastic (HDPE bags) are cheaper, give better yield, good quality oil and sulfur free oil.

You may please comment and let me know your findings, problems etc.

I have been working as a Sr. scientist for Inrex ITLS & Inrex Tests. US (Under exclusivity agreement). My firm is Paramhans Research, work as CRO for many companies.

‘FAITH IS THE ONLY KNOWN ANTI-DOTE FOR FAILURE’

Regards,

Mahesh Pagnis.

+91 9922927097

hello all,i am sateesh from hyderabad medek telangana india.i am advance type plastic pyrolysis plant(plastic to diesel)manufacturer.municipal solid waste like used carry bags,oil pouchs,shampoo pouchs,milk covers,biscuts&food covers,etc.converting to diesel.high yield(per kg waste plastic converting to 700-ml diesel)available in three size.300-lt per day,500-lt per day,1000-lt per day.if you interested person contact me 09348499922,email:hhosys@gmail.com and get more information.

hello sir, i’m interested in setting up a plant in india. i will like to know more about investment and technical issues. establishing process, investment of plant, project report, machinary information. waiting for your information, and where can we sell our sell our fuel too.can u plz mail the full detail on my email id or cell number +91-9820733654

Hi,

Great product you have there. Im interested in setting up a plant in East Africa and am interested in basic specs, prices etc. Please contact me

Regards

dear sir I want to make a homemade plant to convert plastic to oil. thus I want to contribute to the green environment. would you pls help me?

best regard

fazlul hoque

dear sir I want to make a homemade plant to convert plastic to oil. thus I want to contribute to the green environment. would you pls help me?

best regard

fazlul hoque

hello sir, i’m interested in setting up a plant in india. i will like to know more about investment and technical issues. establishing process, investment of plant, project report, machinary information. waiting for your information,can u plz mail the full detail on my email id : ajayjain_ad@yahoo.com or cell number +91-7509287277

Dear Sir / Madam,

We Are interested in your product and to do business with your company .

let us know if you can handle the supply of this your products and also send your

product quotes and item models for selection.

PAYMENT TERMS:The terms of payment is 80% advance payment via (T/T) by

telegraphic transfer confirmed in your account before Production and 20% to be

confirmed as well before shipment.

Delivery Time: 6 to12 months after receipt of your full payment

Awaiting your early reply soon

Reply to My Email Directly on : abc.consult002gh@gmail.com

You Can Call Me On Phone +233 237394058

Thank You, Waiting To Hear From You.

Yours Faithfully,

Richard Owusu – Accredited commission Agent.

ABC 200 ( GH.) SUPPLY COMPANY

Great innovations I see here.

Aslamo alikum,

i am intreasted in this project and thinking to set up a plant and i dont have any idea about its budget what type of plastic will give more benefit etc. so pls can u mail me the all detailed information of this plant…..+92-300-948-7767 (Ali Ahmed) Pkaistan

We are interested in setting up a plant in UAE and Qatar. We would like to discuss further for which we request to contact us on 00971506544860

This has helped me a lot , thanks! What do you use to cool the gases down?

Interested to know about the latest developments and thrie sustainbilities in connection with the subjects mentioned above. Thanks and Regards.

Respected Sir,

I am a Mechanical Engineering student from India.

I would like to know more about this technology as a student I would like to take this topic as an engineering project.

Sir, I have a lot of waste silage bale wrap and old tyres can i make them into oil.

hello sir, i’m interested in setting up a plant in india. i will like to know more about investment and technical issues. establishing process, investment of plant, project report, machinary information. waiting for your information,can u plz mail the full detail on my email id :satheshs6788@gmail.com

I want to start plastic plant in Thane . I want to know about investment , space required , machinery and kind of oil and produced from this plant

hello sir, I’m interested in setting up a plant in India. i will like to know more about investment and technical issues. establishing process, investment of plant, project report, machinery information. waiting for your information,can u plz mail the full detail on my email

hello

i am prakash patel from gujarat

i have new plant.

continues type waste plastic pyrolysis plant

it can make fule oil from waste plastic

capacity of this plant is 4 to 6 ton of waste plastic

i want to sale this plant ..if you are interested to buy this plant please contact me on +91 9925729895

for photos and video of this plant contact on whatsapp +91 9925729895

THANKS