When you think of heating with fire, the first image that might leap to your mind is a crackling wood stove, the mainstay of cozy homesteading living rooms everywhere.

But despite it’s current ubiquity in back-to-the-land imagery, the wood stove is a relatively recent invention, having been invented by Benjamin Franklin in 1742. If you really want to know about true homely coziness, the way humans have enjoyed it for millennia, not merely a handful of centuries, then you need to go further back in time and get to know the Masonry Heater.

What is a Masonry Heater?

At the risk of being too obvious, a masonry heater is a heating device that is made out of some sort of masonry. This can be as simple as an oven made out of mud (that is then dried and hardened), or as complicated as a many-chambered floor-to-ceiling structure made out of brick. Many have a door that can be closed during firing, while others don’t.

All masonry heaters are heavy, or more accurately, massive. They are made to be as massive as possible so that they can absorb all the heat that is produced within its firing chamber and then release that heat slowly over the course of hours or even days (depending on the size of the heater).

History of the Masonry Heater

It is not possible to say where the first masonry heater was used or who came up with the idea to use one. I would guess that there actually isn’t a single origin. People have certainly always known that stone was good at holding heat; I mean, even lizards and snakes know this. So, it probably didn’t take people long after learning how to make fire to figure out that it was a good idea to enclose this fire in masonry of some kind. Over time, as housing and heating units became more and more complex, the heaters eventually came to resemble modern masonry heaters.

As I already mentioned, I figure that the masonry heater originated in multiple locations across the colder regions of the globe. This is supported by the fact that we see masonry heaters all over the world today, and they have all sorts of different shapes, sizes, and complexities. Some were, by external appearances, simple stand-alone units; a few were made to heat the floor, like the Roman hypocaust; while others integrated a bed or sitting area around the heater. Germany, Russia, China, Sweden, and many other countries have a long history of masonry stove construction each with their own particularities and design specifics.

How does a Masonry Heater Work?

The most important concept to understand when trying to grasp how masonry stoves work is THERMAL MASS. Thermal mass is a measure of the heat storage capacity of something. Think of thermal mass as a battery, but one that stores heat energy rather than electric energy. Simply put, something with a high thermal mass can store a lot of heat.

This is the exact reason why masonry stoves are so massive. The more mass that you can put into the heater, the more heat the it can store and the longer it will give off heat. This is why such massive materials – stones of various sorts, mud, brick, and tile – are used in the construction of these heaters. They can all absorb a great amount of heat energy and then release it over a long length of time.

At this point, I should mention that it is very common for people to confuse thermal mass with insulation. They are very different. Materials that are very good insulators have very low thermal mass, and things that have high thermal mass aren’t the best insulators (although they do have some insulating potential). Think of your generic pink fiberglass insulation. It is made of many fiberglass strands that are loosely woven together in a thick mat. This allows for a lot of air to be trapped in those spaces. This makes it very lightweight with a low density (and therefore a terrible material for thermal mass).

The whole point of insulation is to prevent the transfer of heat from one area to another, while thermal mass is used to hold onto heat. As far as masonry heaters go, you want to build them out of materials with thermal mass, and then save the insulating materials for the outside of your home to prevent the heat from escaping.

Basic Masonry Heater Design

As already mentioned, masonry heaters are constructed in place from massive materials like stone, brick, mud, and/or tile. They are literally constructed from the ground up. Being so massive, they all start with a very strong base that will be capable of supporting a few thousand pounds. Trying to construct one in your average home with normal stick frame construction would be a bad idea. It should either be constructed on a concrete pad that rests on the earth itself within the house, or you will need to add some serious bracing underneath where it will be constructed. It could be a good idea to consult a structural engineer in such a case.

Concerning the actual heater itself, the designs are myriad and varied. Trying to go through every different design would take a book rather than an article, so I will not endeavor to do such a thing. Instead, I will try to highlight what all masonry heaters have in common.

The design starts with the firebox. This is the compartment where the fire is actually contained. It should be located on a convenient part of the heater (usually the front). The most efficient designs will include a door that can be shut tightly. This door will either be solid metal or metal with a heat-resistant glass viewing window. They should come with a frame that is set directly into the masonry work.

The firebox must be lined with a special sort of brick called firebrick. The firebrick can withstand the repeated high temperatures to which it is routinely exposed. Typical brick found in your local hardware store will not be able to stand up to this sort of treatment. Many of those bricks are made of concrete and are liable to explode when they are in such a high temperature environment. It is well worth the extra expense to get these firebricks.

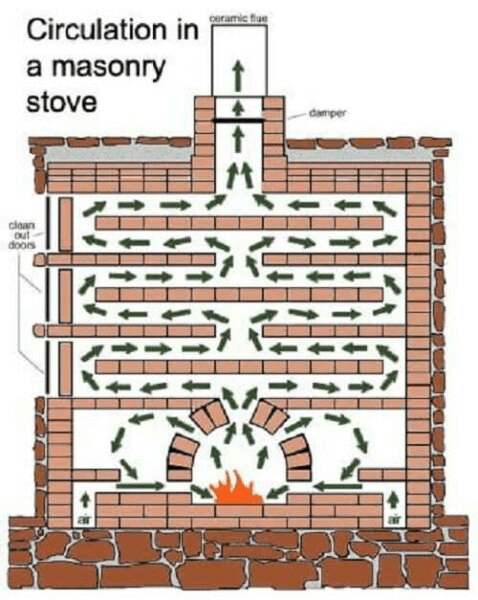

The next part is the most difficult part of the design. From the firebox, you will have a series of passages that will wind through the body of the heater. The simplest designs have only a single channel, while the most complex (and efficient) will have multiple channels through which the gases will travel. The point of these passageways is to suck out as much heat as possible before the gases actually escape through the chimney. This is central to efficient masonry heater design.

The final part is the chimney – the chimney connects the masonry heater to the outside air. All of the flue gases, now deprived of their heat, must exit the home. This can be through an existing brick chimney, if your home has one, or through a newly installed system. Many of these will be thin-walled metal pipes. The most common system is composed of single-walled black pipe with a 6” diameter for those portions on the interior of the home and double or triple-walled stainless steel pipe for the exterior portions. These two parts are connected together at the exterior wall or roof with a specifically designed thimble that ensures that the pipe meets minimum clearances to combustibles.

How do Masonry Heaters Compare with Modern Metal Wood Stoves?

While they are both devices designed to heat a home using wood, they do so in very different ways. I wouldn’t say that either is better or worse than the other – it all depends on how you wish to use it and how your home is designed. So, let’s go over a few of the major differences of the two.

Masonry heaters are generally more expensive

A small metal wood stove can be bought for a couple hundred bucks. They even sell cheap conversion kits that can convert a metal barrel into a wood-burning stove. However, an EPA-certified metal stove designed to heat a home of 2000 sq. ft. will start at around $700 (not including all the required accessories like stove pipe and whatnot). Of course, you could build a dirt-cheap masonry stove from mud that would certainly be cheaper than even a low-cost metal stove, but most professionally-built masonry stoves are going to be priced in the many thousands of dollars.

Masonry heaters are more difficult to install

Installing either a metal stove or a masonry stove is probably beyond the purview of the average DIYer. In either case you have to make sure the floor is strong enough, the clearances to combustibles is adequate, and the flue and chimney are up to snuff. That being said, a masonry stove is just more difficult on almost all accounts. First, it has to be built in place literally from the ground up, while a metal wood stove is fully assembled when purchased. In a masonry unit, the fire box, the chambers that the gases pass through the unit, and the external structure must all be assembled by someone proficient in working with masonry.

Masonry heaters are slower to heat up

All of that mass take a long time to heat. In a metal wood stove, you can begin to feel the heat almost as soon as the fire starts. That is because you are only working with a few hundred pounds of metal. It heats up fairly quickly and can then give that heat off to the room. However, with a masonry stove, you might not feel any of the warmth for a good long while. That is because you have to heat up all that masonry before it begins to give any warmth to the room.

Masonry heaters are more efficient

By their design, masonry stoves are meant to be heated by a high heat fire for only a few hours a day – yes, one time a day. By contrast, a metal stove needs almost constant feeding of wood during the day (and night in especially cold weather). You can buy the most efficient metal wood stove and it will not even come close to the efficiency found in a well-designed masonry stove of appropriate size.

Masonry heaters are more aesthetically pleasing

While a fire crackling away in a metal wood stove is admittedly a thing of beauty on a cold winter’s day, during the time that it is not in use, a large hunk of black metal is not something all that nice to look at. However, whether or not there is a fire in a masonry stove, it is a work of art. It will function as the centerpiece of your home, and will certainly be a focal point of conversations with guests.

Masonry heaters are safer (especially for children)

The surface of a metal wood stove can reach upwards of 700 degrees F. This is hot enough to cause instant burns on anyone who accidentally touches it. In contrast to this, a masonry stove with a 6” thick wall will barely get to 140 degrees F on the outside surface with a 900 degree F fire on the inside. And this pleasant heat is why beds and chairs are often incorporated directly into the design of many masonry stoves.

Masonry Stoves are naturally off-grid since they predate the electrical grid by a few thousand years or so! However, despite their ancient technology, they are as relevant–and perhaps, even more so–today as they were when they warmed our ancient ancestors around the world.

35 Amazing Masonry Heater Inspirations

Here are some of the best masonry heater ideas out there.

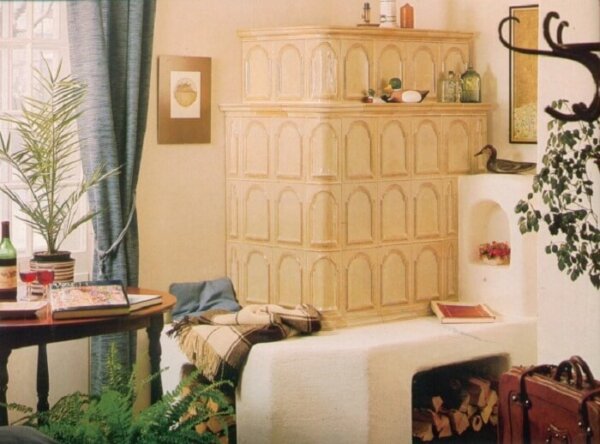

Kachelofen

Masonry heater – new stove based on an old design. A Kachelofen is a ceramic tiled wood stove which has mazelike, masonry channels within. The meandering exhaust gas warms the surrounding masonry which then slowly radiates its heat. A small windowless door allows the fire to burn very hot inside the heater. High heat and the addition of a second combustion chamber, burns up the polluting volatile gases and efficiently turns them into heat. For more examples go to biofireinc.com.

Kachel Tiles

Tiled Kachelofen by biofireinc.com. Special ‘kachel’ tiles surround the internal fire brick.

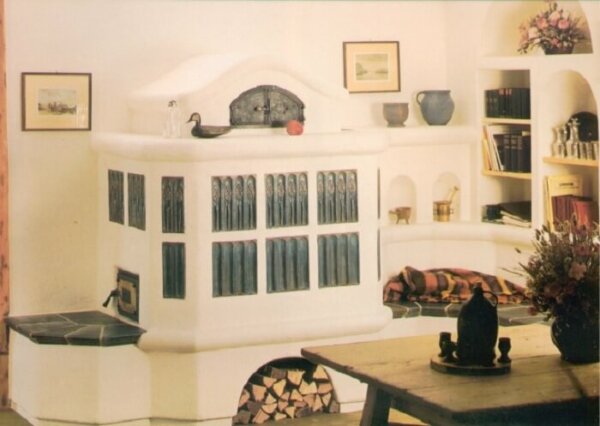

Stucco And Tile

Stucco and tile masonry heater. Additional information can be found at fliesen-ofen-ritter.at.

Old-Fashioned Heater

Old fashioned masonry heater clad in stucco and tile. Fliesen+Ofenbau Ritter GmbH, have additional information on their website.

Rustic Masonry Heater

With a black trim, this masonry heater adds a touch of class to any room.

Asian-Influenced Heater

Tiled masonry heater with Asian influence. Only special ‘kachel’ tiles can touch the inner firebrick, all other tiles must be spaced away from the inner masonry, otherwise they will crack. Additional images can be found on fliesen-ofen-ritter.at.

Heater With Stucco

Stucco and tile masonry heater. biofireinc.com The small door keeps the heat inside, so high combustion temperatures are reached more easily.

Finnish Masonry Heater

Tiled masonry heater in Finland. The Finnish government encourages the use of masonry heaters with tax incentives, the program has been so successful that 90% of new homes have masonry heaters. More photographs like this can be found at contura.eu.

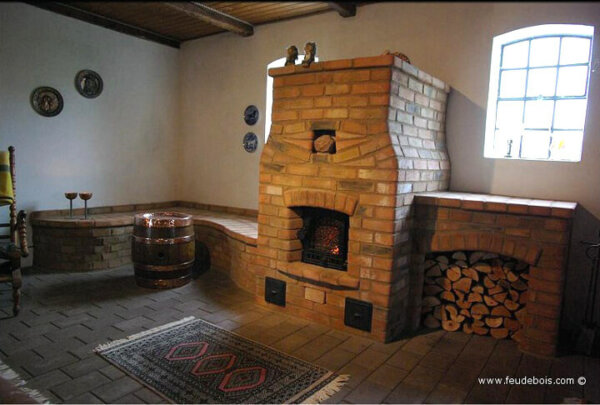

Heated Bench

Brick masonry heater with heated bench in Denmark. A heater with a façade thickness of 3-4 inches, gives a moderate heat transfer, not too fast, not too slow. By Lars Helbro. Originally found at stenovne.dk

Mountain Heater

A masonry heater can be a great way to keep a cabin or mountain home heated. Not only do these heaters provide an eye-catching centerpiece, but they are efficient.

Cozy Reading Nook

Brick masonry heater in Denmark by Lars Helbro. For additional ideas visit stenovne.dk.

Heating Wall

This masonry heater acts as a wall between two rooms in Quebec, Canada. By maconneriegillesgoyette.

Reclaimed Brick Heater

Brick masonry heater made with reclaimed brick, sand and lime mortar, lilac bluestone and a Heat-Kit heater core. By William Davenport, turtlerockheat.com. To reduce stress, masonry heaters in North America are usually built with a double-wall system; a refractory core including firebox and channels or baffles, and a separate, unattached masonry veneer. Otherwise the heat of the firebrick might crack the façade, although brick is least likely to be stressed.

Carsten Homestead

Masonry Heater with wrap around heated bench, direct fire oven (on kitchen side), and wood storage by Carsten Homstead of Massachusetts. Originally found at homespunworks.com.

Rustic Heater

This masonry heater in Burlington, Vermont has a bake oven on the kitchen side. Masons: William Davenport, Spencer Blackwell, Norbert Senf. Turtle Rock Heat has more information and ideas on their website. Originally found at turtlerockheat.com

Heater With A Core

Stone masonry heater with a heatkit core. If there is too much façade mass, 5″ or more, the mass can slow down the heat exchange. An efficient heater should produce heat at the same rate as the heat is emitted. The firebox size should also match the size of the heater and home.

Indoor Heat

It is not efficient to put your heater on an exterior wall. When on an exterior wall, that portion of the masonry facing toward the outside, will simply be heating the outside air. This heater is an interior wall. Vermont masonry heater by smithandvansant.

Heater From Canada

A masonry heater’s chimney can be ceramic or metal. Large fireboxes reduce combustion efficiency and generate higher emissions. Keeping the window small means the heat gets absorbed into the masonry. Canadian heater by bien-o-chaud-portail-poeles-et-foyers. Originally found at bien-o-chaud-portail-poeles-et-foyers.com

Soapstone Heater

Soapstone tiles give a modernized style to this masonry heater.

Brick Heater

Brick masonry heater. There is no reason why some heaters can’t be low and long. There is a wood fired cookstove on the opposite side of this heater. More images can be found at stenovne.dk. Originally found at stenovne.dk

Centralized Location

Masonry heaters are best positioned in the center of the home. The kitchen side of this heater is faced in brick. Massachusetts heater by Steve Bushway, ultimateridgehook. Core by heatkit.

Slate Heater

Local slate covers this masonry heater in Vermont by William Davenport. The heater has doors on both sides. Turtle Rock Heat has more information on their website. Originally found at turtlerockheat.com

Heater With Concrete

Masonry heater that extends to room on other side of wall. Custom concrete slabs, steel, black walnut wood box top, bluestone, lilac bluestone. Originally found at turtlerockheat.com/charlotte.html

Tulikivi Heaters

Soapstone masonry heaters come in all sorts of shapes and sizes. Soapstone has thermal properties that exceed all other stone, brick or stucco. These Tulikivi heaters are at the virginiaradiant showroom. Pictures of a Tulikivi being put together: mha-net.org

Heater With A Window

Masonry heater with large see-through windows. A large firebox reduces combustion efficiency and generates higher emissions. See-through heaters also increase the amount of heat escaping the firebox and therefore lowers combustion temperature and generates higher emissions. Visit brunner.de for additional information.

Heated Bathroom

Masonry heater in a bathroom by peacedesign. If the distance from the core to the surface of the stove is very thick (5″ or more) or complicated (many layers), the heat will radiate out very slowly. An efficient heater should produce heat at the same rate, as the heat is given off (emitted). A massive heater will also be much slower at responding to changes in temperature.

Mosaic Heater

Stucco and mosaic masonry heater. Core is by Heat-kit. More information is available at mha-net.org.

Heater In New York

Grey colored tiles have a clean appearance, making them great for a modern style.

Masonry Heater For A Two-Story Home

In a two story home, this is one of the best locations for a masonry heater. A complete gallery of this heater is available on erdwerk-keramik.at.

Miodula Hotel

Masonry Heater in the Via Miodula Hotel, Poland. You can find more images at villamiodula.pl.

French Stove

Masonry stove in France by poele-cuisiniere.fr.

Heater With Earth-Clay Plaster

This masonry heater is veneered with the same earth-clay plaster used on the walls of the main floor. A heated bench topped with sandstone makes for a warm perch on winter days. By Gimme Shelter Construction. More photographs and descriptions can be located on gimmeshelteronline.com.

Masonry Heater Build Guides

- Design plans for small cabin heater in brick: firespeaking

- Lots of ‘inside’ pictures/designs/lessons: firespeaking

- Manuals: mainewoodheat

- Masonry Heaters: Planning Guide for Architects, Home Designers and Builders. By Alex Chernov. stovemaster.com/files/masonry.pdf

- Core construction manuals, kits start at $5400: heatkit

- Cob masonry heater with bench, handprintpress

- Masonry Heater Planning Guide: tempcast

- Step by step photos: mha-net.org

Masonry Heater Resources

For further information, check out the following resources:

- The Book of Masonry Stoves, David Lyle

- Chinese Kang Bed-Stove: https://en.wikipedia.org/wiki/Kang_bed-stove

- German Kachelofen: http://www.stovemason.com/kachelofen/

- Ancient Roman Hypocaust: https://www.unrv.com/articles/roman-hypocaust.php

- Deer Hill Masonry: https://www.ultimateridgehook.com/deerhill/recentprojects.html

- The Masonry Heater Association of North America: https://www.mha-net.org/html/gallery.htm

- Missouri-Designed Masonry Stove: https://archive.org/details/masonrystove

An original version of this post was written by Kieren Fox.

Sorry, but two pictures with this text: ‘Brick masonry heater in France by feudebois.com’ are made by me, not feudebois, and they are not in france, but in Denmark.

Jerome Previux do not have my permission to put his copyright on these pictures.

Best

Lars

Thank you for writing. Such beautiful work you do by the way!

So sorry about that, due to the copyright stamp I thought they were by Feudebois. I have changed the credit and link to you…

Kachelofen- Is there any information on the round, green and cream tiled stove pictured on this site? (Last stove pictured) And thank you for setting up such a nice site.

Hi Ron, So sorry, I could not find any info on that stove… I try my hardest to find the source of images, but had no luck here whatsoever. If ever I find the source, I will definitely post. Thanks for writing. Best!

Wonderful images!

We’re planning to install a ‘kachelofen’ into a home we’re building. I am looking for practical advice to allow meto begin imagining a potential design and the info on this site has been very helpful. Thanks very much!

Are there any good publications dealing in depth with the internal flow design parameters?

Hi Ken, Great project!

I added one plan for a kachelofen above in resources…lots of youtube videos like this one: youtube.com/watch?v=fdGikgPjmUE

There seem to be more kachelofen plans on youtube than other places…but might take up a whole day to see them all… I think I should do a whole page on just kachelofen in the near future…please check back! Best!

From an image search I deduce that the makers of the tiles for the green and cream stove are Iwona and Jerzy Jarmołowiczowie, from Lechów, near Bieliny, in south-cental Poland.

jarmolowicz pl / category / media /

More about the home with that stove:

adelaparvu com / 2013 / 12 / 05 / a-dat-parisul-pe-o-casa-inconjurata-de-pini /

What a nice page you made!

For interested self builders: you can find pictures of the builing of our stove on finoven.wordpress.com.

It’s a finnish contraflow type in loam blocks, with a heat exchanger on top that powers our hot water supply and underfloor heating for the rest of the house.

Since, in a ‘normal’ wood stove installation one has to have the chimney liner ‘swept’ periodically, I am wondering how the internal passages in these stoves are kept clear and free of creosote? I realize that they probably stay warmer than the usual chimney but we never run our wood stove overnight despite promoting condensation when it is started cold the next morning.

Thanks

Creosote is made when wood fuel is not burnt efficiently, the is the hallmark of a ‘normal’ metal box wood stove. The main reasons is the lower combustion temperatures of metal fire box; they take as much heat out of the fire as quickly as possible and throw it out into the room, and when you shut the fire down because it’s too hot or to extend the fuel life, the temperature drops even more. This is a nightmare for pollution, and a great recipe for sticky hydrocarbons like creosote.

Masonry heaters burn wood much hotter, they reflect heat back into the fire for more complete initial combustion, and then what isn’t burnt in the primary combustion is completed in the secondary chamber which has another air draw to light the hot gas mix, so they have very little of these hydrocarbon gasses that stick to the chimney. They solve the overheating of a room with thermal mass, so much hotter, shorter burns.

In any case there is normally an access to secondary chamber / chimney, but from what I’ve read / seen, there is very little carbon buildup, it all gets burnt close to 90% efficiency.

mass stoves only burn at high temperature for a couple of hours

Anyone out there know of any masonry heaters that are also used to heat a sauna (up to 180 degrees) as well as multiple other living environments.

Thanks

Good morning.

I want to build a brick stove with heat exchanger inside.The stove should be with smoke bell(s),not with smoke channels and the power should be 12KW:6kw for heat exchanger and 6kw for stove to heat two(2) rooms.Do you have free plans to find some ideas how to build a mass heat stove?Thanks.

Best regards

George

Romania

Good morning.

I want to build a brick stove with heat exchanger inside.The stove should be with smoke bell(s),not with smoke channels and the power should be 12KW:6kw for heat exchanger and 6kw for stove to heat two(2) rooms.Do you have free plans to find some ideas how to build a mass heat stove?Thanks.

Best regards

George

Romania

Is anyone building these in the U.S,A. and can they meet the increasingly stringent regulations for wood stoves? Not that I think they would be unsafe just that the regs were written with a different sort of stove in mind.

Is it possible to use a pellet burning heating core in a tile stove? If so, where can they be purchased?

I would like to purchase a smaller tile heating unit for my smaller home (1200 sqaure feet) in BC Canada

Great pictures! For a how to, see Thomas J. Elpel’s, ‘Build Your Own Masonry Fireplace’ DVD.

hopspress.com/Videos/Masonry_Fireplace.htm

I am Austrian trained in the calculation, design and construction of Austrian masonry heaters. We are located in British Columbia Canada but are happy to travel to install a custom built Austrian masonry heater.

If anyone has any questions, about masonry heaters, please feel free to visit our website and email or call me.

Sidl Masonry Heating

http://www.masonryheating.com

What a wonderful consolidation of information!! The textured patterns on the sides made reading this even more pleasurable.

I have environmental damage to my heart and lungs (metal thieves burning copper wire near my home!) and thought I’d lost the ability to heat with wood. Masonry heaters may be an answer.

Thank you!

Can anyone tell me the real differences between masonry and rocket mass heaters please? What is the difference in fuel efficiency?

from buckarest-Romania

I am a specialist in build execution with contraflow chanells,austrian sistem it s the best from the world!Why i say that,because i learn this works from italian big master in the Rome and Univesity of Bologna(only one years testing and experiments all the system stove masonry)and this italian has 45 years experience in this stove masonry!From Claudio(the italian big master)i learn everythink about this stove system and tell my a lot of secrets from this works,because a was handle works 6 month an 3 years like worker from himself supervising.After 14 years working in this stove masonry,in north of Italy,in the mountain zone,i can discover a verry good system after one years in experiments,with a boiler/register/ in the stove wich can make 60 kw heat for all the rooms from a big house,with an instalation wich has a pomp for recirculation all the termic agent,and make the heat in all the house uniform,from the radiators in each room.The real efficiency it s from 78-85% with small consumption.For example,at my house 125 sqm,i need 18 kw ,and at -25 gr Celsius,i have a consumption around 25-35 kg /day/24 hours,and 2-3 times to feed ,the register it s a revolutinary,i made a system with 3 air of nourishment in centre/focus(heart of the stove) and from 5 at 7 chanells for flue,and is working verry well.I am verry sory for my english writte,but i think you understend what i try to explain.The russin system it s russian rullet,big consumption more than 50 kg for 24 hours ,at maxim 6-7 kw,need a big place/space in the house,and it s verry dificult at execution an build,only the russian can build tis system ,has a lot of secrets and if you don t know the secrets, you can make only a big sheet!Russian system it s maybe equal with austrian system chanells,maybe only a good worker from russia can make this system in double bells or bell!Another good system it s coming from danish and scandinavia, around 78-84% efficiency,real not lyer,ok!If is it someone intresting about my system you can sent my an email at adrianos68.rai@gmail.com,or mobile 0040737755579,and maybe I can explain system better than here!Good luck,bye bye !Adrian

I’m building a log home in the country & want to to heat ~2400 sq/ft (1200′ on two levels) with a Russian stove. No area masons are comfortable building one from plans so, I need to find sources for a prefab kit to be assembled on-site. Names & contact info. of kit suppliers please.

Bill,

Did you ever find an area mason or a kit for your log home?

I have a 4,000 three story log home in Nevada in which I need a lot of help in.

Thank you.

Bill Kelly, Please feel free to contact me at info@masonryheating.com

http://www.masonryheating.com

Hi,

This is a great resource! We’re interested in building a masonry stove for ourselves, but are struggling to find information about the specifics of the baffles to make sure that they draw correctly. Is there anywhere where you can get plans and measurements to understand more about how to make them properly?

Thanks!

We are trying to find a source for glass doors appropriate for a masonry heater. Our firebox will be about 28 inches square, and we’d like to have as much of that area visible as possible. Does anybody have any leads?

Hi Cheryl,

We supply one sided, double sided and corner glass doors for masonry heaters as well as all other necessary material.

Feel free to contact me for more information,

Carl

info@masonryheating.com

http://www.masonryheating.com

I had very good luck with building my own stove, designed by Alex Chernov of Stovemaster. See contact info above. Alex was very helpful with his email advice.

I found many of my materials in Craigs List, and saved a good deal. My stove looks nice, works great, and it was the first masonry brick project that I ever built. I’d be happy to talk with you about it. Contact me at:

jstassek@btc-bci.com

This past fall we built a masonary heater using the heat kit design out of Quebec. We have a wrap around heated bench that the smoke goes through after it leaves the heater core before it goes up the chimney. We are having condensation problems in the last half of the heated bench. In the first hour of burn we get condensation in the bottom of thr heated bench that is made with 8’x12′ clay flue lineers. The water pools in the bottom of the flue linners in the heated bench and leaks out through the cracks in the joints of the linners used to make the heated bench. The liquid seeps out of the motor of the field stone facing at the bottom of the heated bench. Even though we have several inspection doors we can not get in physically to caulk all the joints in the flue liners in the heated bench. The flue linners were mittered and fitted well. The joints were motored with high temperature motor that has cracked after a month of burning it. The temperature in the first hour of burning is too cool in the heated bench allowing condensation. The liquid will start to evaporate after the first half of the burn if it has not leaked out already. Has anyone else had this problem and is there any way to solve this without dismantling the whole heated bench? Thanks for your help.

regarding Dave’s condensation issue. You may not be heating your heater up enough. To light the stove at the start of the heating season, I make 2 small fires each day, 2nd day I go larger on the fires, till I have full load fires on the 4th day. After the 2nd day, there should be some heat beginning to soak through and in reality, the inside cores should remain hot (over 100C) for the whole heating season. There should have been instructions with your kit. Inside the firebox, by the 4th day, should only be bare white masonry, with only traces of black soot in the corners. The fires should be hot, and about 2 or 3 hours long.

Condensation happens when stuff is cold. Either your heater never cured and dried out, or you have not heated it hot enough.

Kits. We built our heater in California in 2012, after a year of red tape to get approval for the TempCast kit. Our model has a wonderful door that they may sell separately. tempcast com They sell core kits and ship them with excellent packing,

And thanks inspirationgreen com for this informative page

Mike

Dave,

I’m no expert here but seems to me if you’ve been burning your stove for a month or longer it must have dried out by now. Are you sure your firewood is well-cured and dry?

Thank you your replies. This heater is located in Western Canada in a unheated house. The house is around freezing when we have been burning the heater. I was hoping to use it to heat the house while we drywall and finish the inside of the house. The heater is on the main floor and sits on top of a 3 inch thich cement pad that is supported by steel floor trusses. The concrete pad under the heater and the basement is around freezing for temperature. There seems to be no difference if I burn 15% or 30% moisture wood. I still get condensation even on the second burn of the day when the heater core is hot. Even if the heater is hot the heated bench is luke warm to the touch. It seems I can not get enough heat produced to get the heated bench real hot. A 50lb load of wood heats up the core nice and the facing stones get quite hot. The air in the heated bench clay flue linners will finally warm up enough later in the burn to start evaporating the condensation. Is there any way to seal up the flue liners or spray in them to make them water tight or will we be faced to take the heated bench apart to get it sealed up properly? If a guy ends up redoing the heated bench is there a type of concrete that a guy can use instead of the clay flue liners so a person can have one continuous trough with no joints that can take expansion and contraction without cracking? Thank you for the help and suggestions?

I have a Tempcast stove in my 1990 house. Living in the country, most of the fireplace professionals have no idea how to clean and maintain this stove. Since they don’t know, they tell us it’s not safe (and, of course, want to sell us another system, lol) We want to make sure that we are maintaining a safe heating source. I’m having quite a time trying to find out what is necessary to maintain a 25+ yr old masonry system. Any suggestions of steps, resources, etc. would be most appreciated.

there are some youtube clips on starting and maintaining the Ecco stoves that may help you and your sweeps.

If anyone knows about a stove building course running soon in Europe? Similar to this one, which provided welcome heating to a rural school in Hungary.

https://www.stenovne.dk/englishpage%20course.html

It would be nice to have some traditionally trained Hungarian builders on board too, even if just to visit and advise, like the group who came to the UK with expert skills and their locally available materials for this stove.

https://www.dailymail.co.uk/news/article-1041812/The-medieval-marvel-14th-century-Hungarian-stove-cuts-monthly-gas-just-5.html

I can understand why my previous post didn’t get past the moderator and should have been more positive. USA pot-belly stoves made sense at the time, an AGA made sense 100 years later, now things are evolving quickly and not everything regarding safety and DIY indoors is going to be perfect! The main thing is that having worked around hot furnaces and kilns, growing up with stoves, the idea of a solid fuel DIY ‘flue’ in the form of a masonry heater which all living spaces and bedrooms have access to is not dealt with by the current codes. I cannot understand why particulates matter, but children’s fingers and hot stoves and hot glass cosmetic doors do not! A mandatory fireguard would spoil the ‘cool’ image, but at least demonstrate a more responsible attitude to design principles in general. Children under 5 can’t read or always remember if told the Operating Manual, which is all that is required to pass EN code.

I have the scars.

Mark

Great article. We have a modern version of our own, made from ceramic, at Cornish Masonry Stoves which you might like.

Mark, your link leads to an old site i allmost have forgotten.

If you want to know about WS in Europe, look here: https://www.stenovne.dk/englishpage%20intworkshop.html

I havent yet updated for 2017, but the traditional WS on The little island Drejoe in Denmark will be there every year.

Its not correct to call masonry heaters medival. Ive seen a stove in Catalonia build by the romans 2000 years ago. Of course they have improved since, not the least the last 30 years.

I make work-shops everywhere on request, so if anybody have interest, just contact me.

I allways use local materials if possible. Itsno help to teach how to build a good stove in Spain out of danish materials 😉

Best Lars

What a great source of information! I experienced living with this type of stove in Kitzbühel, Austrian Tirol, in 1959-60 and have always wondered why we didn’t/couldn’t have them in Canada. Now we are moving to BC (Vancouver Island) and I am hoping sometime next year we could consider having one installed in our new home, thanks to the explanations given here. But we would need an expert to do it, so I look forward to doing some more exploring on the possibilities described here. A big thank you to everyone who contributed to this discussion!

Hello Christina,

We at Sidl Masonry Heating specialize in the design and construction of Austrian masonry heaters (Grundofen/Kachelofen) and are located on Vancouver island. Feel free to contact us if you have any questions. http://www.masonryheating.com

Best comprehensive article with resource links I’ve found during my quest to know more about this topic. Thank you!

Good afternoon. I recently purchased a building and found the stove in the attached pictures inside. I’ll be demo’ing and remodeling the space and was wondering if you or one of your members could give me information about it? I have no use for it, but do not want to wreck it. Thanks…

Hey Mark,

That’s pretty interesting, do you have photos you could share?

You might want to try posting in one of the regional forums of Permies.com, and see if it’s the type of thing anyone wants to salvage or purchase? Otherwise I’m not sure what you could do with it, other than demo or leave it as-is.

Just wanted to say thanks for this great post. So much information!

Photo/Attachment:

Hi! I was hoping you could help point me in the direction of selling my in perfect working condition, 1982, German Waso wood burning coal fireplace ceramic stove cast iron. It’s stunning! I’m thinking someone would love this beauty, but don’t know where to start. I can send you pics, but it looks like this.

Hi – we moved into a new house and now we have that same 1982 fire place. I can’t find a user manual anywhere on line…would you be able to send some instructions? I know it’s in working condition, but I don’t know exactly how to get it started. My email is courtgregory@comcast.net.

Thanks so much!

Great information.

Are any of these units EPA rated ?

Photo/Attachment:

You should have a pic of the Archgard Salzburg XL+1 as well – I will attach a picture of mine. When I built our house 14 years ago I included a foundation for a site built heater which I never had the time or money to install until now. Recently, I got a quote for the fancy soapstone heater which is beautiful no question but it was 3X more expensive than the Salzburg! And the Salzburg was here 3 days after ordering and was built in a day. There was a 6 month wait to get the soapstone heater and a week to build. In the end, it was pure luck we found the Salzburg which is not well advertised in NA but it is popular in Europe. It’s super modern which fits our house 100%. And its more efficient by a few percent too! If you don’t need a custom built unit and you want something more efficient and modern then definitely check out the Archgard unit. This is my first wood heater and I’ve figured out how to run it without getting any smoke in the house. Next up is figuring out if we can cook a stew in the firebox after a fire!

Oh – BTW I think the Salzburg is not more popular because they are too easy to build so the mason’s wouldn’t make any money building them so they lost that marketing channel. I think it’s an oversight because they can still be customized and faced with tile or stone if you want so they can still get creative and run up the tab. And a beautiful site built stove is a work of art. Thing is I need heat and can’t afford art right now. I painted mine a funky yellow (painting is mfr approved!) so you can get creative and paint it all crazy if you like and change it as your tastes change. I don’t want to say “no brainer” cause that’s not nice but for the average person – this is an affordable way into a high performance masonry heater.

I would like to know if it´s possible and how to heat different spaces in a one story home; can one channel the heat or does it only work for open plan architecture?

Temp Cast of St Paul Park, MN produces and sells a pre-cast refractory core around which a 4” masonry veneer may be constructed. Kits include hardware, instructions, etc. Videos are available on YouTube. There is also buying information online.

Is it possible to build a masonry stove over an existing wood stove? Using the wood stove as the fire box? My stove sits on ceramic tile on a Alaskan slb.