Of all the building methods in use around the world, none go back as far as building with mud. Indeed, it would be reasonable to assume the first dwellings humans had were made of earth instead of caves. Mud is abundant and freely available for the taking anywhere on the face of the planet that’s fit for habitation. Building a simple home out of mud also requires no specialized tools or skills. Of course, larger and more complex structures will require a certain expertise and engineering knowledge, but a DIYer of average skill should be able to build a more-than-serviceable building without much difficulty.

What Is Cob?

Cob is clay, sand, straw, and water mixed into mud, formed into shape, and then allowed to dry rock hard. The cob forms a monolithic structure that has a high amount of thermal mass and decent insulative qualities. Clay and sand used in the mixture most often come from the soil on site. Some sites will have soil that is perfectly suited for use in cob without any amendments, but others may need additional sand or clay – more on this later. Traditionally, a cob house is covered with a thatch roof, but modern cob homes have a wide variety of roofing options from metal to living roofs and everything in between.

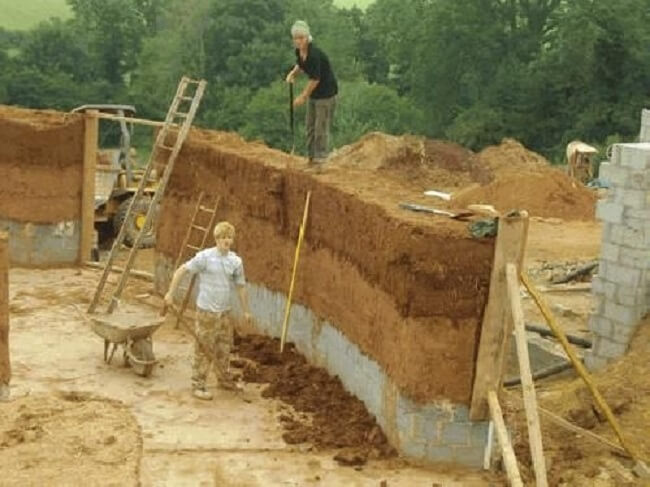

How Do You Make Cob?

Cob is fairly easy to make. Once you have either found or made the right mix of clay and sand, you need to mix it with water and straw to make cob. Mixing can be done in several different ways. Traditionally, people would dig a shallow pit in which to mix cob. It can still be done that way, but the modern invention of a tarp makes mix cob easy.

When mixing cob, lay out a tarp. If you are doing it by yourself, the average 6 inch x 9 inch works fine. On top of the tarp, put a few 5-gallon bucketfuls of your dry dirt mixture. Make an indention in the middle of the dirt and pour in some water. Now you mix the dirt into mud using the tarp. You will lift alternating sides of the tarp which causes the dirt to mix with the water. Once you have a thick mud (you don’t want it runny), you will add chopped straw by the handful and continue mixing by lifting the tarp. Eventually, this process will form a thick and sturdy mud that will stand up under its own weight. At this point, it can be put on the wall where you will use it.

I should also mention that you can also mix cob using your feet. This method makes cob using less energy than the above as it requires you to lift the weight of the dirt less. You still lay out a tarp, but instead of lifting alternating sides of the tarp (which does get tiring after a while), you step on the mixture and combine all the materials with your feet. It is quite easy to mix cob this way, so I do recommend it. However, if you have sharp rocks in the dirt mixture, or it is cold outside, it may be best not to use the bare feet method.

What Are Some Important Design Considerations When Building With Cob?

Dry Feet

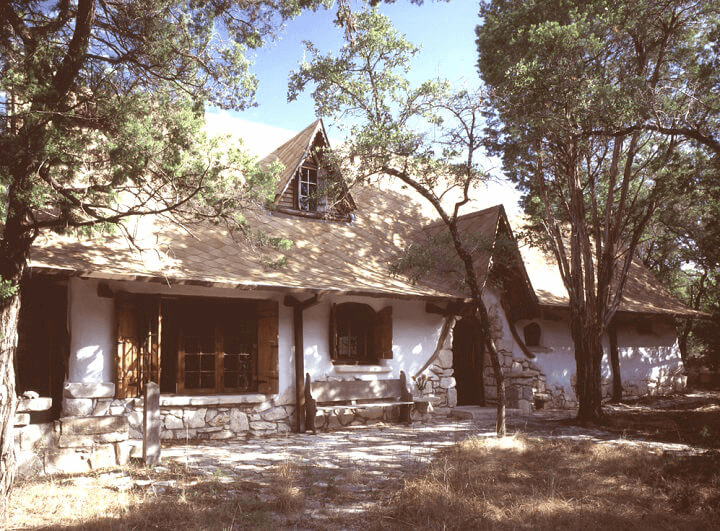

Having “dry feet” refers to the fact that cob cannot be built directly on the ground as it would be susceptible to weakening and possible collapse from ground water. Cob must be built on a wide, strong, foundation that raises it above the ground. Traditionally, the foundation was made from large stones found on the site. Modern cob homes can still use the traditional stone foundation, or a concrete foundation can be poured. Whatever is chosen as the foundation, make sure to consider the following three things. First, that it is wide enough. Cob walls are often almost 2 feet thick at the base for a single story home. Second, that it is strong enough as cob wall are very heavy and a foundation will need to support all this weight. Finally, that it is high enough to isolate the wall from ground water, including water splashing up from hitting the ground around the house.

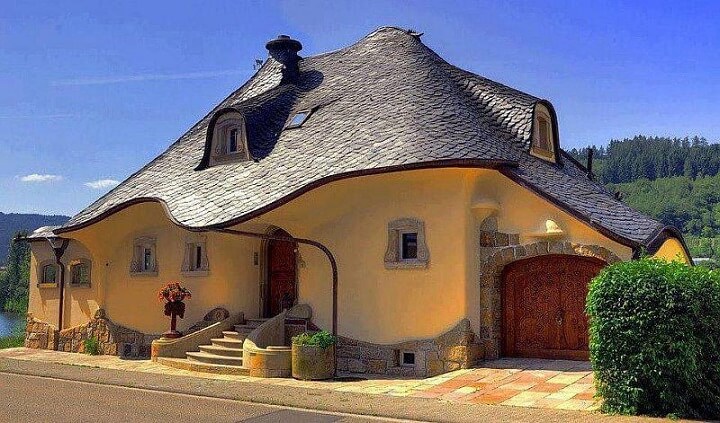

Wide Hat

In addition to having dry feet, a cob house must have a nice wide hat. Of course, this expression is referring to the roof. Water coming up from the ground is only half of your concern when building a house of cob; the other danger is water from above. In order to prevent rain from getting on the cob walls as much as possible, a roof with wide eaves and overhangs should be built. Again, the roof was traditionally made out of thatch, but you can put whatever sort of roof you want to on your cob house so long as it has generous overhangs to keep the walls dry.

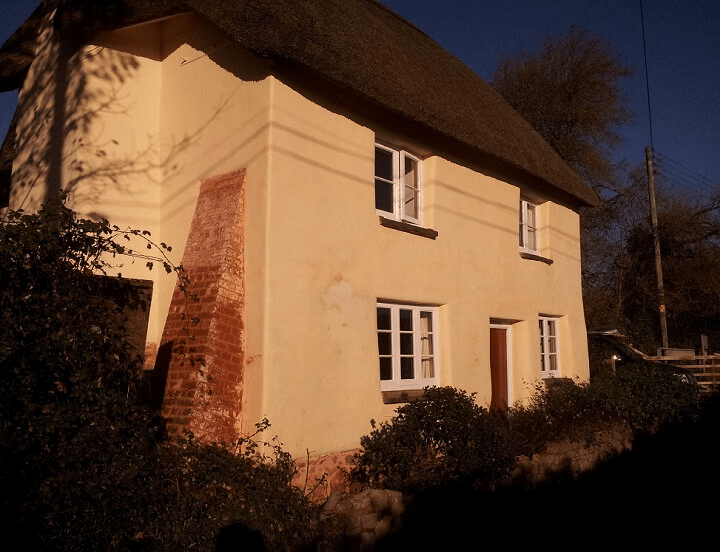

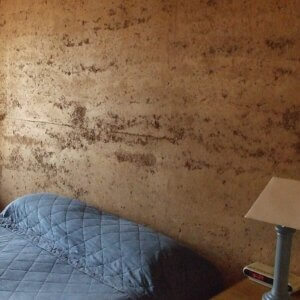

A Good Coat

The surface of the cob needs to be covered to help the cob become more weather resistant. Usually, the cob is covered with a lime plaster and lime wash (also known as whitewash). It is important to use lime plaster and NOT cement plaster. Centuries-old cob building were “repaired” using a cement plaster and these buildings quickly deteriorated because lime plaster breathes while cement does not. The moisture that gets in the wall is able to escape from the lime plaster, but cement keeps it in which will eventually destroy the wall.

The Right Mix

As mentioned earlier, some soil directly from the ground contains the perfect mix of sand and clay. However, many places will have either too much sand or too much clay. And just to be sure we are on the same page here, we are talking about the subsoil on a site — do not use top soil in your cob mix (there is too much organic matter in the mix and it is too valuable in the garden anyway). In cob, you are shooting for around 20% clay and the rest sand. Gravel can also take up a portion of the sand as it makes the cob stronger, but it also makes it more difficult to mix by hand (or as is traditional, feet). When you mix up test batches, if your mix has too much clay, it will form cracks. If it has too much sand, it won’t hold together well. You can do soil tests to determine the percentages of sand and clay in your particular soil, but I generally make up a small test batch of cob and go from there. It is evident what needs to be added by how the cob sets up. If it cracks, I add more sand. If it crumbles, I add more clay.

The Right Fibrous Material

Just a quick, but important, note on the type of fibrous material to use in your cob mix. You must use straw, not hay. Straw is composed of the stems of cereal grasses once the grain (seed) has been removed. Hay is made up of dried grasses with the flowers or seeds still attached. This makes hay especially nutritious for animals but not so good for your wall as some of these seeds can sprout on the surface of your cob. Make sure to buy straw when building with cob.

What Are the Advantages of Cob?

Low Cost and Wide Availability

As with many alternative building techniques, cob is dirt cheap. Aside from the cost of purchasing straw, the materials for building with cob are free for the taking if you have a shovel or a friend with a backhoe. As the Earth is made of, well, earth, dirt is easy to come by. Finding the right sort of dirt might be somewhat of a challenge at first, but digging several holes around your property will usually avail soils of different compositions that can be mixed to make a nice cob.

Ease of Construction

Once you get the hang of it, it is fairly easy to make cob. I mean, even children like to make mud, right? Once the cob itself is made, putting it on the foundation and forming walls is not a difficult endeavor. The most difficult part is making areas for windows and doors, but that is not a huge challenge.

High Thermal Mass

One of the main advantages of cob is its high thermal mass. Thermal mass is its ability to capture energy in the form of heat and release it slowly over time. Cob has the ability to store vast amounts of heat from either the sun or another heat source (like a wood stove), and then release this into the home over many hours or days. Thermal mass also helps the temperature in the house stay more constant.

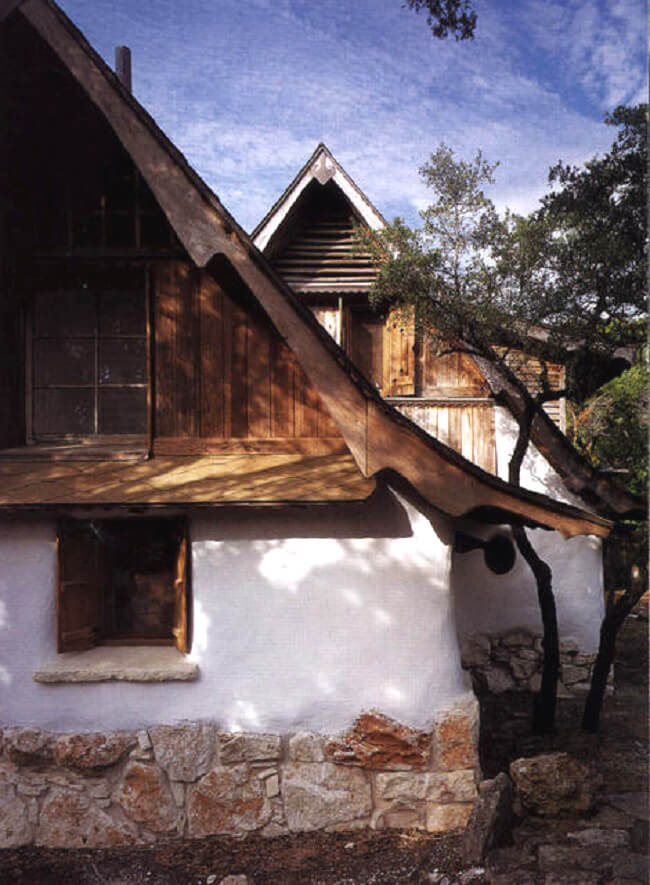

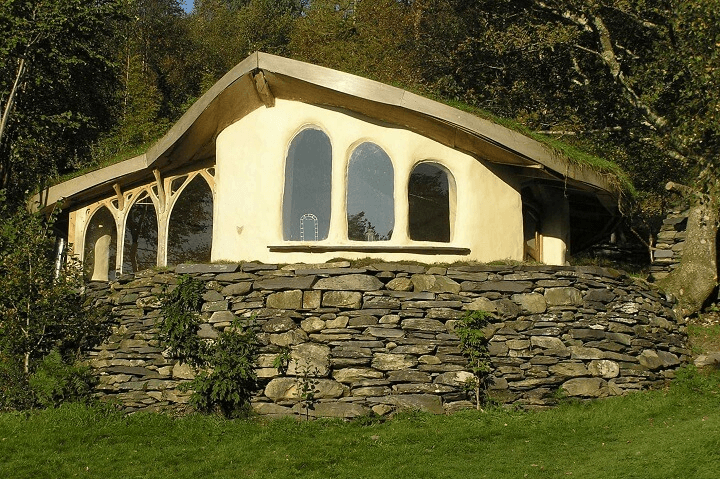

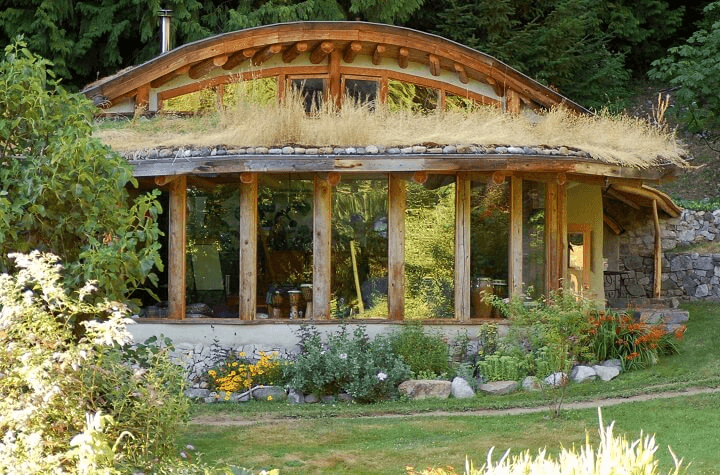

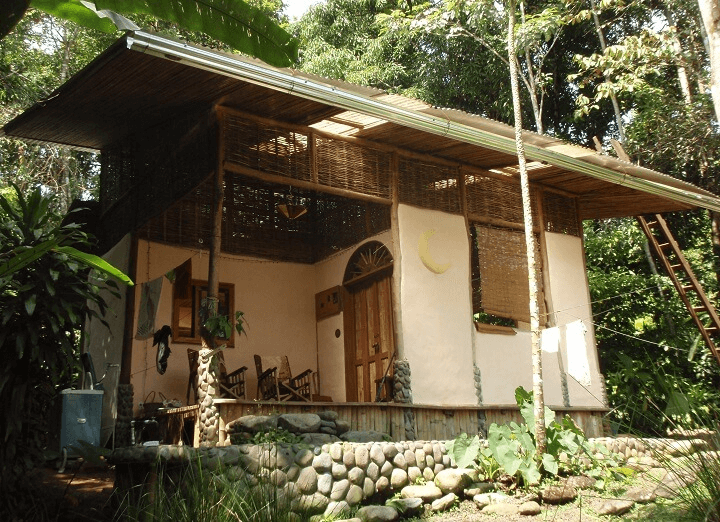

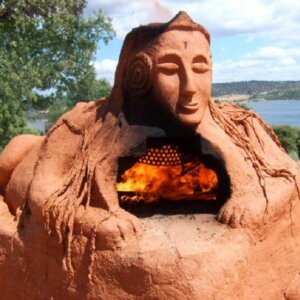

Some Pictures for Inspiration

Hopefully, this article has helped you decide if cob is the right building material for your needs. And to give you some further inspiration, take a look at these pictures of homes that people from around the world have built using this method. Enjoy!

This article is updated from an original version by author Kieren Fox.

It all looks good and I am all about conservation and less resources yet safety still comes to mind. How does it hold up under a earthquake and does it meet with most earthquake building code standards ?

Type cob earthquake/ seismic test into youtubes search bar and see for yourself.

In this case use a woodframe inside The walls. Not so strong tô suport The weight but strong enougth tô suport torcion forces.

This is the first time .. I saw this types of house which is made up of mudd … I really like it …

Looks amazing.